So I have applied for my IVA test anu d panic has begun. It got off to a bad start when I received my forms back in the post saying i had sent them to the wrong place. There is actually different forms to fill in and amateur build form is also different if you live in Northern Ireland even thought we are part of the UK so anyway I hand delivered the forms to the Mot centre in Boucher Road Belfast.

Anyway I finished by binnacle cover I was never to happy with just a single bracket supporting it so I added some stud bar and bonded on a couple of brackets to the chassis.

So this completely stopped the binnacle from moving. On the cover itself previously I had drilled the plastic but it had cracked so this time I bonded on some brackets and used some more stud bar to secure

Some orange plastic paint and some vinyl wrap and final result is a very secure binnacle and cover

I could not get my binnacle perfectly flush with bonnet because I can't lower the steering column any more as my buckets seats sits higher than the mx5 seats and my knees would hit steering wheel.

I made a manufacturers plate and added the compulsory but rather daft Iva sticker regarding dot 4 brake fluid.

I still need to fully weld my Vin plate

I have fulled trimmed all the wishbones and thanks to John I got some electrical grommets in B&Q and used these to cover the track rod ends and used nut covers everywhere.

I also added some extra brackets to secure the brake lines

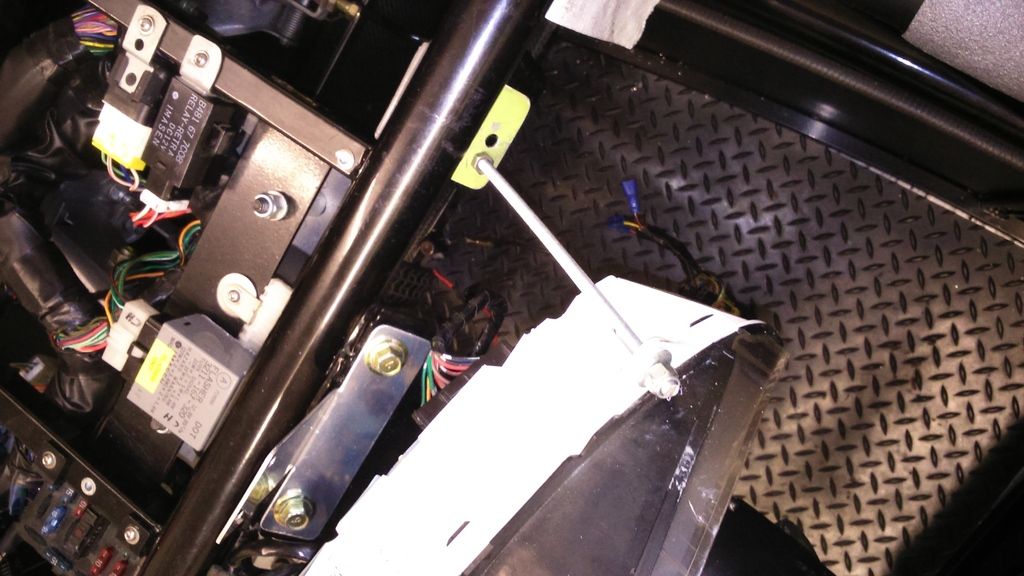

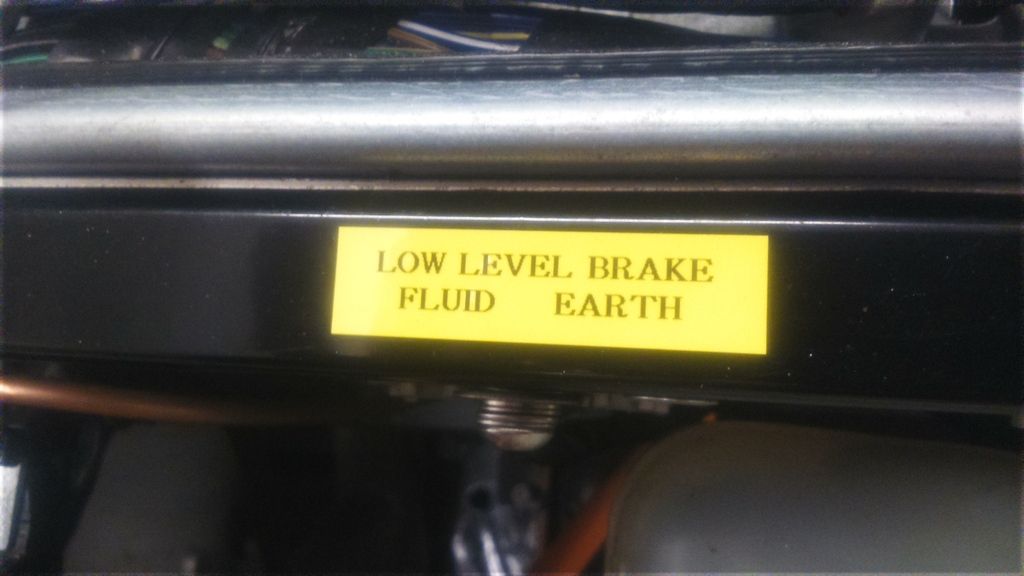

I then labelled every earth and relay for example

My Ecu was previously cable tied in so did not think Mr Iva man would like that so cut existing brackets which I kept and bolted in place. I also used somme 3 mm rubber under ecu to cushion it

I removed unnecessary connectors. Be very aware of shared earths I came across 3 of these and when you cut them weird and wonderful things happen. Cable tray tied up

I removed 2 full bags of connections here is one of them

I also made a bracket for the diagnostics box

I also read on John and Lukes build they had an issue with the low level brake fluid so I prodded mine and it works so happy with that.

I then decided I need to sort this drip tray to stop fuel in the case of a leak from the tank onto the exhaust so I removed the tank. I have made a template and I will then bend some alloy to suit and using a few self tappers I will secure to the subframe. It needs a few bends as the diff sits higher that the subframe

I have also added a fuel tank earth.

One wee piece of advice is when you fit the front wing stays make sure they sit horizontal. One of mine was sitting way up and when I fitted the wing it did not sit right. I can't believe I did not notice it but I had to bend the stay to horizontal. This then resulted in the holes etc no longer lining up and as a result a scrap wheel grp cover. Also don't forget to torque front hubs nuts to 140 lbs ft and re ident then replace cover

On the rear wheel stays I replaced the caliper bolt with a 10 mm longer one. The bolt is a m10 metric fine and I used a spring washer under the head

Big thanks to a couple of people in helping me get this far John Gilbert, Trident Chris and George Gymwar, others and this forum otherwise I would of been completely beat