|

|

Post by tlight on Feb 24, 2011 16:16:13 GMT

All holes (that we can think of) have been drilled, prior to powder coating...  The lorry collects the chassis @ 8am in the morning for powder coating, next picture will be of a nice shiny signal red chassis ! |

|

|

|

Post by bobsox on Feb 24, 2011 21:54:32 GMT

I can't wait to see the chassis in red Tim, it's going to look awesome!

|

|

|

|

Post by tlight on Feb 25, 2011 8:31:13 GMT

Got up early & added a few more holes along the top of the engine bay bulkhead after seeing Alex's updated photos last night (the neighbors will love me). Powder coaters arrived bang on time, chassis due back early next week....  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Feb 25, 2011 11:02:35 GMT

Tim, good progress. Looking forward to seeing the powdercoat in red! I recon I've drilled about 300 holes in total, as it's impossible to get the right placement first time, luckily with brake hoses and fuel lines etc theyre all covered and out of sight. It's a case of fitting things as you go along and moving them around as other things are fitted like wiring and lines. I decided to carpet the aluminium as it's so soft and got covered in dirt and scratches and was full of incorrectly drilled holes!! Advice would be either cover it during the build or take it out once fitted. When's the frame due back?

|

|

|

|

Post by tlight on Feb 26, 2011 7:09:23 GMT

Alex,

Jospeh recons we have drilled circa 200-300 holes. Fingers crossed frame should be back Tuesday. Will post a pic as soon as...

Tim

|

|

hag

Newbie

Posts: 7

|

Post by hag on Feb 28, 2011 0:07:33 GMT

This is a fantastic build thread Tim and Joseph, as a newbie, it's inspirational and informative.

I shall be following this with great interest;)

|

|

Andy888

Full

Exocet Builder

Exocet Builder

Posts: 212

|

Post by Andy888 on Feb 28, 2011 0:17:39 GMT

That's an awful lot of holes!!! Is there any advantage/disadvantage to doing all that prior to powdercoating?

|

|

|

|

Post by tlight on Feb 28, 2011 7:57:43 GMT

Reduce the risk of scratching the nice fresh powder coat in build process.

Plus no break to the powder coating (rust leaching) - though I doubt it will see much exposure to rain water...

Tim

|

|

|

|

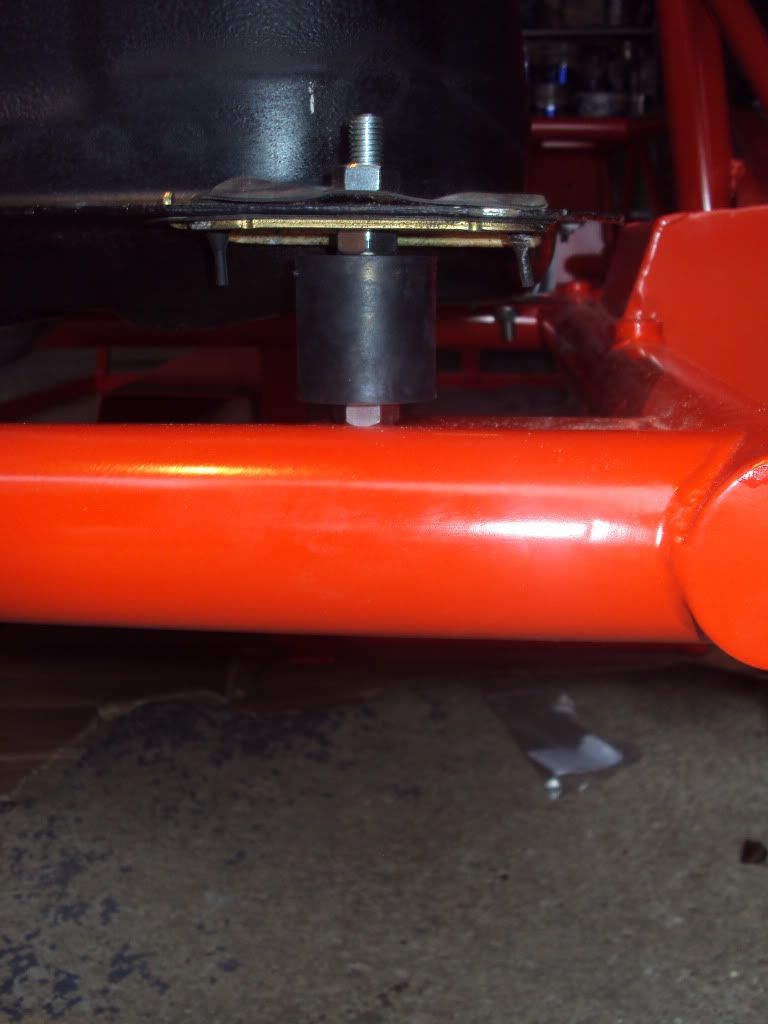

Post by tlight on Mar 1, 2011 11:07:20 GMT

The chassis has returned from Phoenix Engineering, powder coated signal red;   Rear...  |

|

hag

Newbie

Posts: 7

|

Post by hag on Mar 1, 2011 11:38:45 GMT

Looks great, can't wait to see the finished article, some thread;)

|

|

|

|

Post by Kevin Patrick on Mar 1, 2011 14:31:36 GMT

Love the frame in red, Tim!

|

|

|

|

Post by tlight on Mar 1, 2011 15:12:45 GMT

Kevin. Thanks, just come home to find the postman has delivered the 4off isolator bobbins.... 6" ruler along side, with & without M10 nuts  added a nut either end prior to fitment, which made it about 55mm clearance (I reconed I only needed around 40mm).  the stud length, though quite long for what I need, is not visible from the rear (think I'll leave long at the moment as it may aid as a pick-up point for a harness p clip).  and the isolators make a nice tidy job.  Tim |

|

|

|

Post by Stiggy on Mar 1, 2011 17:14:29 GMT

Very smart. Look forward to seeing the grp on or near

|

|

|

|

Post by AdeEp23 on Mar 1, 2011 20:58:25 GMT

Yeah the frame looks great in red  cant wait to see it all assembled  |

|

|

|

Post by tlight on Mar 1, 2011 22:25:23 GMT

Riv Nut gun, applied to front cross member for radiator mounting  Joseph fitting them in the engine bay for the harness and brake pipe P clips.  Passenger floor riveting, after application of silicon sealant.  Sides (best white on red I could do tonight Stuart !)  |

|