|

|

Post by gwnwar on Sept 13, 2016 16:54:55 GMT

You will have to weld a piece of round stock to the frame for the muffler rubbers to attach to.. They were on the body of the car.

|

|

|

|

Post by calibuild on Sept 15, 2016 3:03:30 GMT

Hmmmm, I thought the Exocet wasn't supposed to need any additional welding? That's going to put the brakes on the project since I'll have to do the whole Uhaul thing again. Wonder if I can do it with a bracket / mount of some type.

Was just starting to make real progress too!

|

|

|

|

Post by gwnwar on Sept 15, 2016 5:19:14 GMT

Check newspapers classifieds and yellow pages for welders that will come to your house..

|

|

|

|

Post by zeitgeist on Sept 15, 2016 15:23:37 GMT

You can use a bolt on muffler/exhaust hanger if you want to avoid welding. The stock exhaust will stick pretty far out on an Exocet so you may want to look for alternative exhausts or mounting choices. I am using the Enthuza Exocet version that mounts using the same bolts as the rear fueltank mounts and have had no issues even with track use.

|

|

|

|

Post by SeanW on Sept 15, 2016 16:39:28 GMT

honestly, for the time being, my entire exhaust system has just one hanger on it way out at the back of the car, the set you've circled in red. I need to fabricate a new muffler section that will better tuck-up behind and under the Exocet, for that I'll just use use bolt-on exhaust hangers.  |

|

|

|

Post by calibuild on Sept 19, 2016 7:05:38 GMT

Okay, bit of a delay in posting... but thanks Zeitgeist and Sean! Didn't even know muffler hanger's existed. Gwnwar I may have it welded in the future once I figure our exactly where I want it.

Some progress this weekend, hampered by the local auto parts store shipping error...

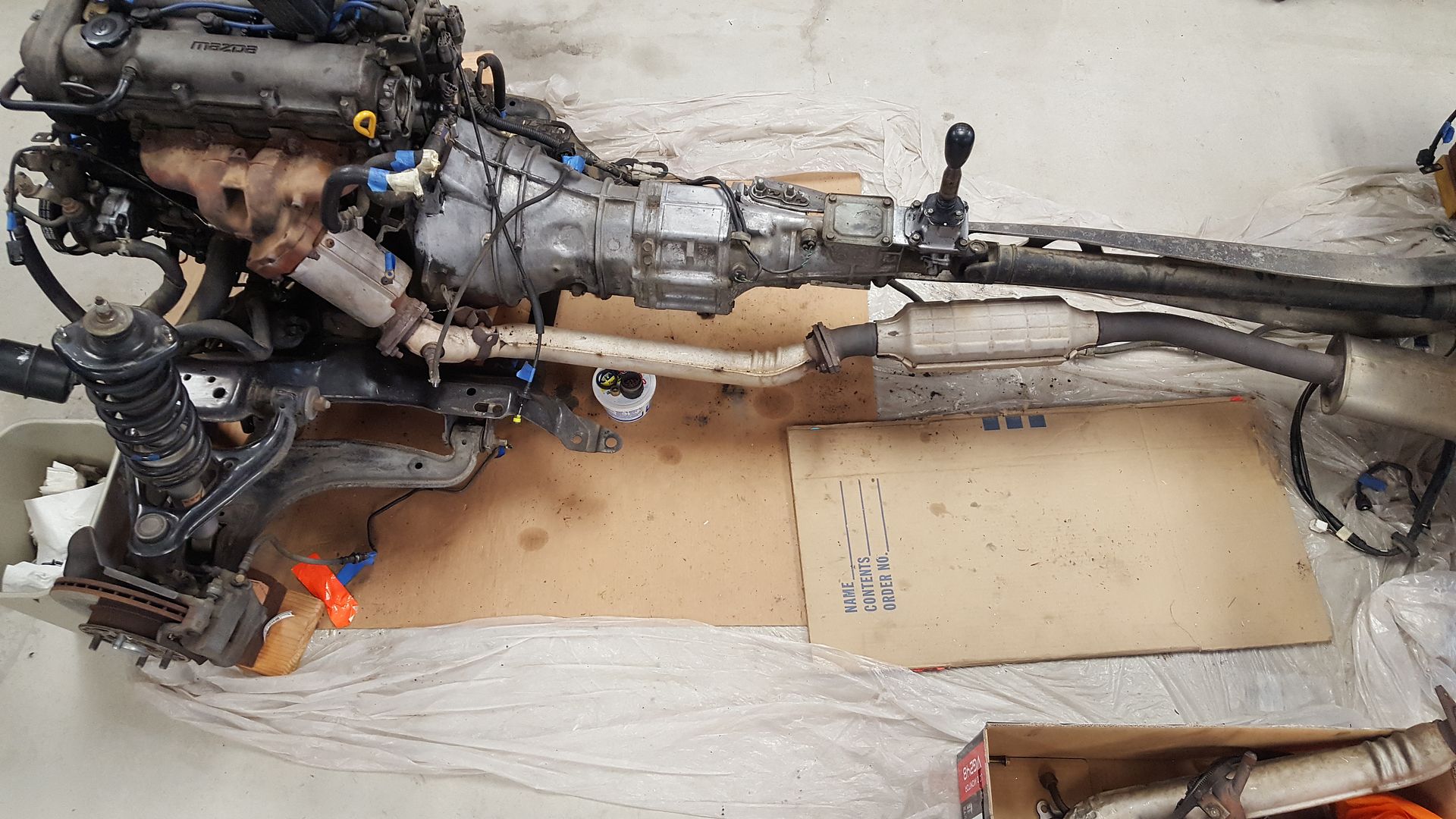

Riveted down the front floor panels, but mostly did the 99 to 01 header swap. The pre-cat was done on the donor, and seemed like the opportune time. There's a ton of threads on this, but I had a really hard time finding pictures, which for a rookie like myself are super helpful. I'll try to make a youtube video or something, but until then... here's the pre-setup (Cali set up with pre-cat), with no heat shield

Here's the post set up, heat shield is back on. Bung has been moved back, spliced the wire to extend (both soldered and used connectors). Also linked the 2 AC pipes up with 1 rubber hose.

Was all set, ready to go, put the frame on.... and the exhaust hits the floor! The swap isn't causing it. You can see it lines right up, exactly where it should. Holes to bolt the frame seem to line up too if I could actually sit it down.

Not sure what to do.... wisdom is welcome  Feel like it's close to getting the frame on. And thanks to everyone for chiming in with thoughts. Feel like it's close to getting the frame on. And thanks to everyone for chiming in with thoughts. |

|

|

|

Post by russ872 on Sept 19, 2016 12:33:44 GMT

Re: exhaust. I cut mine just past the cat, removed the slight elbow just downstream of where I cut, bought a 2" flex hose, used about half of it to join the two ends, rotated the resonator end abut 90-degrees, which made it easily fit in the trans tunnel and the curvy part at the end fits under the support bar at the back. I made a simple clamp bracket from the end pipe to the support bar. No muffler. It's plenty quiet with just a cat and resonator. Cost me $14 for the 2" flex hose and 2 additional U-clamps.

By the way, I'm in Oceanside, Ca.

|

|

|

|

Post by calibuild on Sept 27, 2016 3:42:07 GMT

Woooo! Big progress, finally got the chassis on the roller skate

Updates: created a video on how to swap the 99-00 header to the 01+ exhaust header. The software is rudimentary and the music has to be free, so enjoy Mozart!

Thanks Russ for your input. Did something similar. Cut the exhaust on either side of the resonator, turned it 90 degrees and had it welded back on. It barely touches the transmission tunnel, so I'll have to use something to pull it to the side so it doesn't bump.

Need to order rims, was going to go with black rims on black chassis but now probably going with classic silver. Body is orange, unfortunately the gas tank cover had a 1.5-2.5 inch crack on arrival. Waiting for that to get shipped back. Still much to do... but progress!

|

|

|

|

Post by calibuild on Oct 1, 2016 4:11:26 GMT

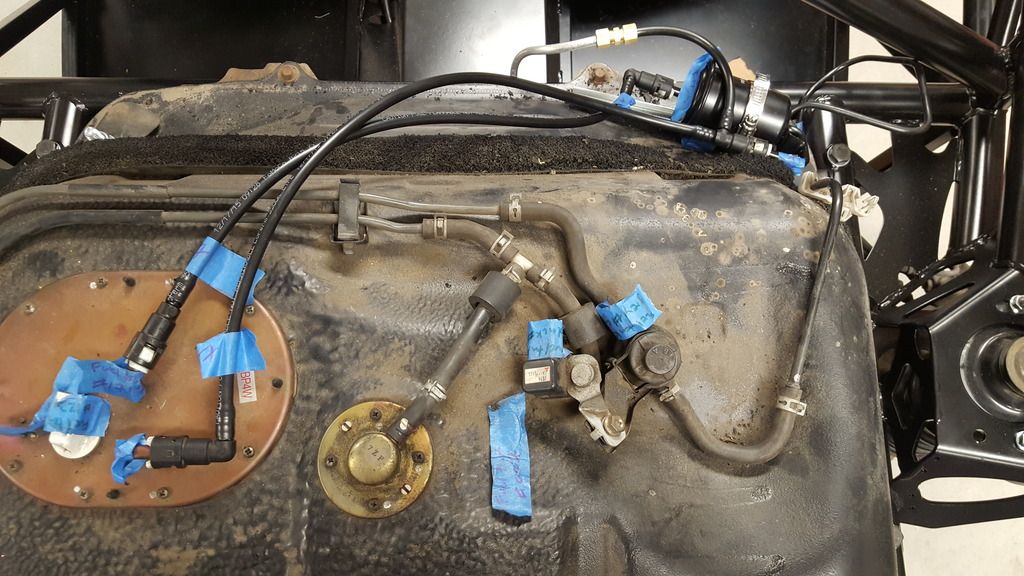

Fuel lines finally sorted! Long learning experience, but got the nylon fuel line, hammered it in (the boiling water process seems crazy). Not beautiful at the moment, but functional  . The brass fittings are great too for going from nylon to metal. . The brass fittings are great too for going from nylon to metal.

The whole charcoal box thing is TBD.

|

|

|

|

Post by calibuild on Oct 2, 2016 17:34:19 GMT

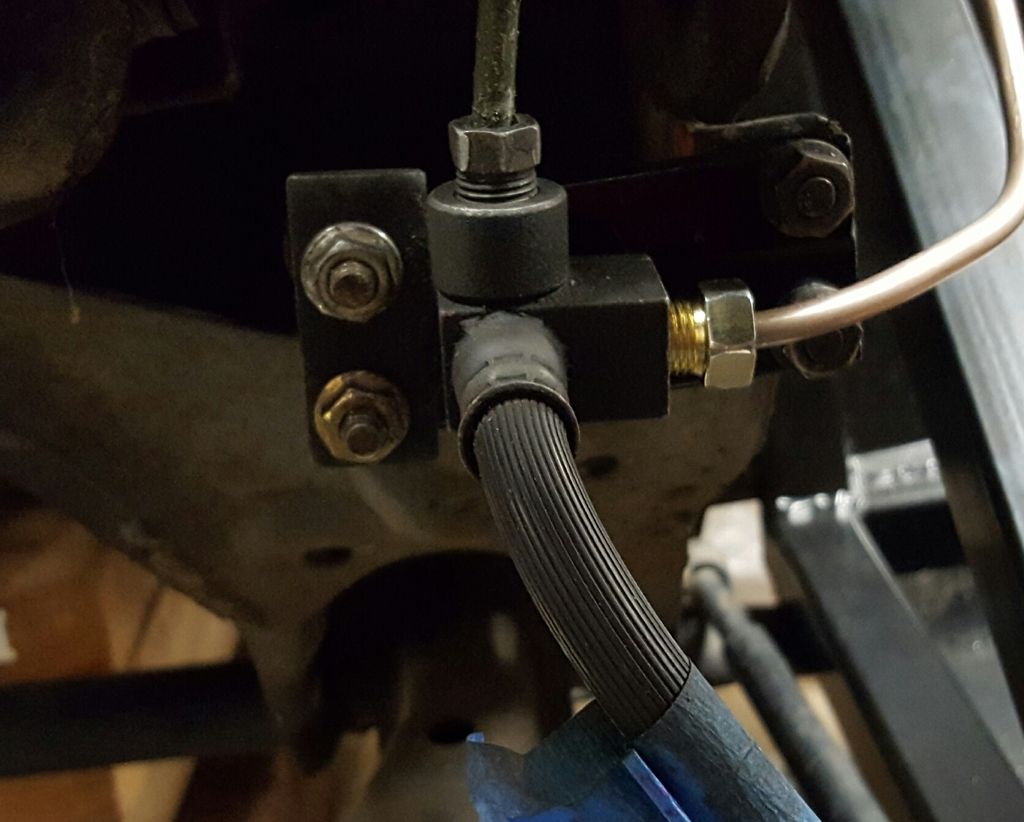

Brake lines done! Had to make a small custom bracket to move the lines back about 2 inches.... now to the floors. Likely going to take a page from "Craig's finished Exocet Turbo" build thread and use studded plastic matting.

|

|

|

|

Post by calibuild on Oct 11, 2016 0:45:34 GMT

Okay, updated a couple pervious post above with pictures  Progress is being made. Progress is being made.

Now I'm trying to figure out how to lay out the engine bay... thoughts welcome. Flyin Miata seems to put the coolant reservoir over by the brake cylinder. SeanW's build (green frame, black hood) has a good pic, but wasn't sure where the reservoir was (it might be the red canister). I was going to put it behind the shock / spring mount, but seems like from the side people will see a bright white box (the coolant reservoir)....

A couple build seems to use a fabricated bracket to mount some of the sensors.... still trying to figure out if the pressure regulator and oil can. |

|

|

|

Post by calibuild on Oct 19, 2016 0:55:29 GMT

Floors before and after  Cutting the rubber was a challenge because the floors a depressed an inch and the parts are curved or have angles. Cutting the rubber was a challenge because the floors a depressed an inch and the parts are curved or have angles.

Also drilled the parking brake. Will have to make a little pouch for it as it slightly rubs the seat, but this was unavoidable. I've seen a lot people weld a bracket to hold the seat belt out from the parking brake line which is cool. In my case, I'll just use washers and longer bolt.

|

|

|

|

Post by calibuild on Nov 2, 2016 1:08:18 GMT

Hi All - about to migrate from the 17 inch rims on the donor to 15x8's. A lot people have done the 205 50 15 stretched. Any quick thoughts on that? 205's are a whole lot less expensive than 225 45 15's, and tread wear is a lot better. Car may be occasionally tracked, but mostly used for commuting so extreme performance isn't necessary.

Also appears Firestone / Pep Boys etcetera won't stretch tires, but am sure a smaller local shop would do it. Appreciate your thoughts.

|

|

|

|

Post by gwnwar on Nov 2, 2016 5:46:44 GMT

I run 205/50/15 on my mx5 no problem.

|

|

|

|

Post by calibuild on Nov 2, 2016 13:54:19 GMT

I run 205/50/15 on my mx5 no problem. Nice! Thanks for the quick reply. Will hope to have them mounted this weekend. |

|