|

|

Post by tojeiro on Dec 25, 2016 0:53:14 GMT

Floors drilled without breaking any drills. Bit of penetrating oil as lubricant and small pilot followed by final size seemed to do the trick. Use a bit of cable insulation on the drill to cushion the drop as it breaks through the chassis rail.  After drilling and deburr I gave each hole a generous dab of Hydrate 80.  Chased out all the drill cuttings with vac and air line combo, then sprayed the inside of the chassis with 3 tins of cavity wax with the special nozzle, also gave the frame a couple of spins to make sure inside of rails were well coated.  Thank god for my Lazy Riveter, doesn't seem like that many rivets but reckon it would have taken me 5 times longer with pliers type riveter. Used light grey Tiger Seal between frame and floor so the joint is filled nicely and it's close to frame colour.  Just to put in half dozen or so rivetnuts for fuel/brake line clips then I can drop it on the roller-skate Messaged John to see if he has any of those cool triple pipe clips left, if not I may have to order 100 and become the next stockholder. mevowners.proboards.com/thread/7571/manchester-build-started-2016Merry Christmas to all hope Santa delivers some nice toys. |

|

|

|

Post by tojeiro on Dec 31, 2016 19:57:04 GMT

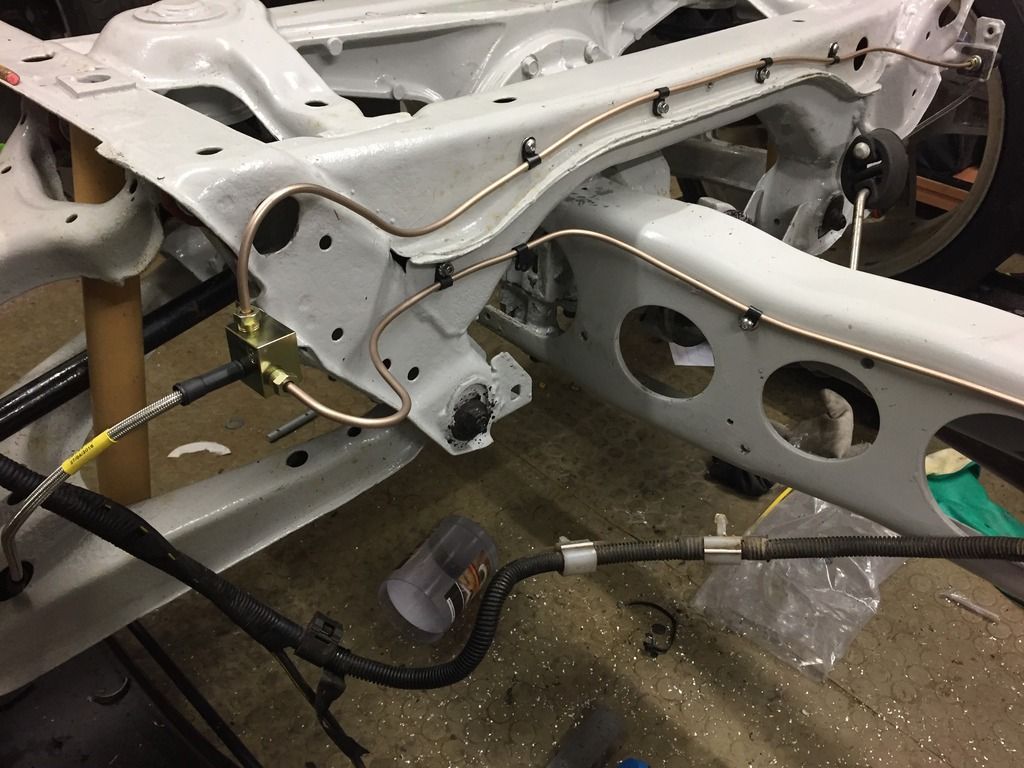

So found a few hours over the holidays to work on the piping. Decided eventually to clip the brake line to the PPF and fuel lines to the frame. Used some extra long rivet nuts thorough the PPF with dome head capscrews so I can always remove the p-clips in future if required.  Need to also p-clip the loom back in place after as a few of the original push fit plastic clips are a bit worse for wear and could be a bit loose, ordered some rubber lined clips for that job. Fuel lines have also been fitted but removed these temporarily until I get the frame fitted. |

|

|

|

Post by tojeiro on Dec 31, 2016 21:45:47 GMT

Question on fuel lines:- I am using cupronickel hardlines which I will make a double flare on the end for joining rubber injection hose - no issues here. The new filter and tank however have the pipe connections designed for the standard quick release couplings (no flare), I would like to reuse the Mazda connectors for these connections and therefore carefully stripped off the orginal hard nylon lines to leave just the barbed connectors.  I did a trial fitting with new hose and proper clamp and seems very secure.  Has anyone else reused these in the same way ? Anyone foresee any issues ? |

|

|

|

Post by R2S on Jan 1, 2017 0:01:11 GMT

Accept I may be missing something here but why aren't you just coupling the rubber line to the filter? Aren't you just introducing another potential point of failure?

|

|

|

|

Post by tojeiro on Jan 1, 2017 0:40:57 GMT

The main issue was that the Mazda filter and tank is designed for the quick release couplings so the inlet/outlet pipes are straight pipes only with a large shoulder.  I was more concerned that with no barb or flare on the filter or tank only friction would keep the rubber hose in place. |

|

|

|

Post by gwnwar on Jan 1, 2017 3:49:25 GMT

I would use the OEM fittings too. Click them on and they stay.. Easy to remove with tool.. Peace of mind..

|

|

|

|

Post by snowbird1 on Jan 1, 2017 15:11:43 GMT

So found a few hours over the holidays to work on the piping. Decided eventually to clip the brake line to the PPF and fuel lines to the frame. Used some extra long rivet nuts thorough the PPF with dome head capscrews so I can always remove the p-clips in future if required  Need to also p-clip the loom back in place after as a few of the original push fit plastic clips are a bit worse for wear and could be a bit loose, ordered some rubber lined clips for that job. Fuel lines have also been fitted but removed these temporarily until I get the frame fitted. |

|

|

|

Post by tojeiro on Jan 1, 2017 22:38:18 GMT

Thanks Snowbird, should have thought of that but it didn't cross my mind until I started to bolt up the frame this morning. Still have reasonable access and my screwed on p-clips will also allow me to easily remove and add extra connections for a short flex pipe. I did buy a hand held flare tool so could split in-situ but prefer making them at the bench where I can check the finished flare more carefully - one of my practice flares did come out a bit squint. Roped in my father in law who had stayed over from Hogmanay to help flip and mount the frame before he escaped this morning - he did get a cuppa and bacon roll for his help.  by -Tojeiro 74- by -Tojeiro 74- |

|

|

|

Post by Stiggy on Jan 1, 2017 23:13:13 GMT

|

|

|

|

Post by tojeiro on Jan 2, 2017 0:54:45 GMT

Oh well, live and learn I suppose, thanks for input, especially where safety is involved. Whole idea was a change from original plan just down to fact that I couldn't find triple pipe clips anywhere. Will figure something out on the chassis railand use the rivetnuts on the PPF to P-clip the loom back on. Regarding frame to PPF bolts the front bolts all seem to be quite short, they are engaged on the nylon but no threads protruding. Subframe is painted not powdercoated so no extra thickness there.  by -Tojeiro 74- by -Tojeiro 74-Not fully torqued up yet but don't see me gaining a few more than a half turn. All front bolts are almost exactly the same. Normal engineering good practice is 2 threads, but is there an official IVA guideline or is it inspectors decision (could not find anything in IVA manual) |

|

|

|

Post by gwnwar on Jan 2, 2017 5:40:02 GMT

Get longer bolts it is your butt on the line.. Don't go cheap now.. For all the good that exhaust shield is doing why not remove all the pieces. If you are going to keep the stock header think about getting it Ceramic Coated. Google "exhaust manifold heat coating" There is a place in UK www.zircotec.com/ There are others too.. |

|

|

|

Post by stevednorris on Jan 2, 2017 10:25:32 GMT

IT will fail IVA unless there are a couple of threads showing through the nut.

|

|

|

|

Post by R2S on Jan 2, 2017 11:14:56 GMT

The main issue was that the Mazda filter and tank is designed for the quick release couplings so the inlet/outlet pipes are straight pipes only with a large shoulder.  I was more concerned that with no barb or flare on the filter or tank only friction would keep the rubber hose in place. I was simply going to push the pipe over the shoulders in the pipe on filter and retain fittings at tank end but following your post I'll take the advice and use the original fittings. |

|

|

|

Post by tojeiro on Jan 2, 2017 12:00:32 GMT

re the bolts I have ordered some 50mm long 10.9 grade items with new nylocs this morning. It was not as much about the cost, these came included in the kit package and assumed from grade that they are frame to PPF mounting bolts. Not sure what others have done. Maybe one for Stuart to check. Re the heat shield it is kind of of permanent fixture on my exhaust as the clamp to gearbox is well and truly seized. To be honest it is actually a bit better condition than the first photo suggests.  by -Tojeiro 74- by -Tojeiro 74-System from downpipe back is full stainless so will replace manifold and downpipe anyway when something suitable comes up secondhand, actually just stuck the exhaust on that the moment to stop me tripping over it in the garage. |

|

|

|

Post by mawdo81 on Jan 2, 2017 12:57:58 GMT

You can get hardline to quick connect fittings on eBay.

|

|