Post by tojeiro on Jul 4, 2019 21:28:45 GMT

Done a few hundred miles now without any major issues.

They only bug bear was the limited shock height on the rear.

Not sure if the Protech shocks have different stem lengths compared to standard shocks or if the MEV shock mount is maybe just higher but did notice when I jack up the car I had very limited droop (3-4”) available which was limited by the stem.

The visible threaded stem section was also 1.5” above the nut after all the rubber bushings and washers were installed. On Mazda manual it’s much less and this is part of the reason limiting travel.

Not a major issue but could mean wheels off the ground on some big yumps and we have quite a few of these undulating roads where I live. On rear I also had the spring mounted wound right up to the top with lots of preload on the spring to get required ride height.

Anyway, below is my solution and may be of help for anyone just struggling with ride height issues.

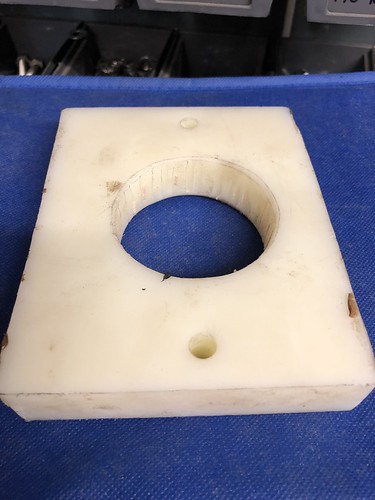

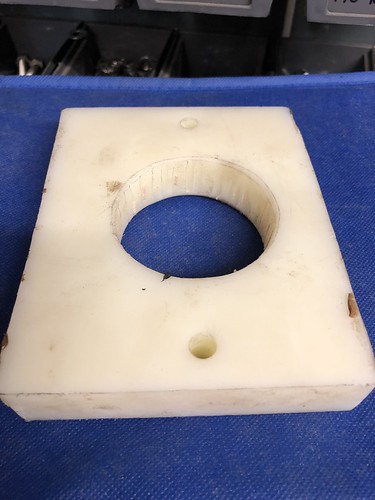

Purchased 25mm solid nylon block - industrial grade hardness, could have used aluminium but cutting 70mm hole in middle would have been challenging. Nylon also has better noise/vibration absorption properties than metal.

by -Tojeiro 74-

by -Tojeiro 74-

As above drilled large hole in centre and two bolts clearance holes to match original Mazda top mounts.

by -Tojeiro 74-

by -Tojeiro 74-

I then pressed out the studs on the top mounts and replaced these with longer HT bolts. I welded these in for convenience. I have a 2nd reason for the longer bolts as I have some tie-rods in the boot giving extra support for my boot.

by -Tojeiro 74-

by -Tojeiro 74-

Not shown but on top of this you still have Mazda rubber bush and large washer so can still be a spanner on to tighten shock stem nut.

by -Tojeiro 74-

by -Tojeiro 74-

Once bolted in it obviously lowers the top mount position gaining ride height.

by -Tojeiro 74-

by -Tojeiro 74-

I had previously made 5mm black nylon spacers to replace the Mazda plastic sheet isolators so just decided to keep them also but actually I now have do much shock adjustment I will take these out.

Also solved the stem extension so have much more suspension droop available when I jack the car up. Instead of spring seat being at the very top of the shock body it is now about 1/2 way down with only minimal preload to avoid loose springs on full drop.

While before the car was fine on fast road bumps, slow rough roads could be a bit jarring regardless of damping adjustment.

First drive out on new set-up was so much more compliant over pot holes and have got now I think the right damping set for all road conditions. Also had 4-wheel laser alignment done at my local specialist who also looks after my TT.

When I get some extra time I’ll pull the nylon blocks off and give a bit of a cosmetic tidy up but anyway completely out of sight day to day.

They only bug bear was the limited shock height on the rear.

Not sure if the Protech shocks have different stem lengths compared to standard shocks or if the MEV shock mount is maybe just higher but did notice when I jack up the car I had very limited droop (3-4”) available which was limited by the stem.

The visible threaded stem section was also 1.5” above the nut after all the rubber bushings and washers were installed. On Mazda manual it’s much less and this is part of the reason limiting travel.

Not a major issue but could mean wheels off the ground on some big yumps and we have quite a few of these undulating roads where I live. On rear I also had the spring mounted wound right up to the top with lots of preload on the spring to get required ride height.

Anyway, below is my solution and may be of help for anyone just struggling with ride height issues.

Purchased 25mm solid nylon block - industrial grade hardness, could have used aluminium but cutting 70mm hole in middle would have been challenging. Nylon also has better noise/vibration absorption properties than metal.

by -Tojeiro 74-

by -Tojeiro 74-As above drilled large hole in centre and two bolts clearance holes to match original Mazda top mounts.

by -Tojeiro 74-

by -Tojeiro 74-I then pressed out the studs on the top mounts and replaced these with longer HT bolts. I welded these in for convenience. I have a 2nd reason for the longer bolts as I have some tie-rods in the boot giving extra support for my boot.

by -Tojeiro 74-

by -Tojeiro 74-Not shown but on top of this you still have Mazda rubber bush and large washer so can still be a spanner on to tighten shock stem nut.

by -Tojeiro 74-

by -Tojeiro 74-Once bolted in it obviously lowers the top mount position gaining ride height.

by -Tojeiro 74-

by -Tojeiro 74-I had previously made 5mm black nylon spacers to replace the Mazda plastic sheet isolators so just decided to keep them also but actually I now have do much shock adjustment I will take these out.

Also solved the stem extension so have much more suspension droop available when I jack the car up. Instead of spring seat being at the very top of the shock body it is now about 1/2 way down with only minimal preload to avoid loose springs on full drop.

While before the car was fine on fast road bumps, slow rough roads could be a bit jarring regardless of damping adjustment.

First drive out on new set-up was so much more compliant over pot holes and have got now I think the right damping set for all road conditions. Also had 4-wheel laser alignment done at my local specialist who also looks after my TT.

When I get some extra time I’ll pull the nylon blocks off and give a bit of a cosmetic tidy up but anyway completely out of sight day to day.