|

|

Post by Kevin Patrick on Feb 4, 2016 19:36:28 GMT

Do it Jon! I built the larger 1000mm X-Carve a couple months back and am absolutely loving it after upgrading the spindle to the Dewalt 611. Regarding the rear fender mounts, I have a one piece rear mount in the works now that I should be able to start testing this spring. Hopefully will test out to be more sturdy and easier to install.

|

|

|

|

Post by ImprobableConstruct on Feb 4, 2016 19:54:35 GMT

I have a Shapeoko 1, Shapeoko 2, Shapeoko 3, and my big router (51"x51" work area) that started life as a S1 and has had 7 major rebuilds in the last 3 years. I also see some upgrade and accessory parts for the shapeoko line. The X carve is essentially the Shapeoko 2 with a few mods and updates. I bought a 3d printer and my S1 at the same time I sold the printer but having a CNC router has been awesome and mine has grown in size and capability with my need and knowledge. The Shapeoko forums are very helpful if and when you run into problems.

|

|

|

|

Post by Kevin Patrick on Feb 4, 2016 20:12:24 GMT

I have a Shapeoko 1, Shapeoko 2, Shapeoko 3, and my big router (51"x51" work area) that started life as a S1 and has had 7 major rebuilds in the last 3 years. I also see some upgrade and accessory parts for the shapeoko line. The X carve is essentially the Shapeoko 2 with a few mods and updates. I bought a 3d printer and my S1 at the same time I sold the printer but having a CNC router has been awesome and mine has grown in size and capability with my need and knowledge. The Shapeoko forums are very helpful if and when you run into problems. Nice! That is one hell of a collection! A 51"x51" envelope would be amazing - I wish I was able to cut half of a 4x8 sheet of plywood. Honestly, I wish I had room for a 4x8 machine. It has been a lot of fun experimenting and trying new things. Last weekend's project was one of the open source Zip Tie Lounge Chairs and a couple of stools. Time to carve in some Exomotive logos. Attachments:

|

|

|

|

Post by gwnwar on Feb 4, 2016 20:24:15 GMT

They better be good heavy duty tie wraps..For us bigger people..

|

|

|

|

Post by jon on Feb 4, 2016 20:44:34 GMT

I have a Shapeoko 1, Shapeoko 2, Shapeoko 3, and my big router (51"x51" work area) that started life as a S1 and has had 7 major rebuilds in the last 3 years. I also see some upgrade and accessory parts for the shapeoko line. The X carve is essentially the Shapeoko 2 with a few mods and updates. I bought a 3d printer and my S1 at the same time I sold the printer but having a CNC router has been awesome and mine has grown in size and capability with my need and knowledge. The Shapeoko forums are very helpful if and when you run into problems. Funny thing, today, after you posted on here, I am browsing some other Shapeoko forums, and I see a user name: "ImprobableConstruct". Hey, I know that guy! I know a fair bit about 3d printing, but my conventional CNC knowledge is more limited. I currently use PTC Creo student version to do all my CAD. I am familiar with the older wildfire from school and work. Anyway, I am interested in doing 3D cuts with the Shapeoko. What CAM software should I use for that? Any you recommend to import STL, just like my printer? I have to check, it may be possible to do the tool paths and g code generation from Creo. I am not sure if the student version supports this or not. |

|

|

|

Post by jon on Feb 4, 2016 20:48:09 GMT

Do it Jon! I built the larger 1000mm X-Carve a couple months back and am absolutely loving it after upgrading the spindle to the Dewalt 611. Regarding the rear fender mounts, I have a one piece rear mount in the works now that I should be able to start testing this spring. Hopefully will test out to be more sturdy and easier to install. Cool! I am considering the X carve too, but the Shapeoko might be a bit stronger? I don't think I need huge sizes, which is probably the main selling factor of the big x carve. That, and I might not be able to fit it anywhere... |

|

|

|

Post by ImprobableConstruct on Feb 4, 2016 22:27:44 GMT

I use Vectric Aspire to generate my tool paths. It does 3D and it very easy to use. The problem is that it is really expensive but you may be able to find an older version. If you are going to stay small then go with the S3 if you want to make it bigger then the Xcarve may be the way to go. They are both capable machines.

|

|

|

|

Post by jon on Feb 5, 2016 20:53:37 GMT

It was still cold today, but not too cold and the roads are salt free. That means driving! I can not wait for spring. Got a few shots of the car and interior outside.    |

|

|

|

Post by steadfast on Feb 5, 2016 21:45:51 GMT

damn Jon, that looks good. The interior looks fantastic.

|

|

|

|

Post by jon on Feb 8, 2016 14:22:47 GMT

|

|

|

|

Post by boileralum on Feb 13, 2016 5:20:12 GMT

What's the width of your grip tape on the floor and where did you get it? I am trying to find something wider than 12" that isn't $150 and 40' long, and it seems impossible. My Google-fu is usually very strong, but I am getting nothing.

|

|

|

|

Post by jon on Feb 13, 2016 6:24:20 GMT

|

|

|

|

Post by boileralum on Feb 13, 2016 15:11:30 GMT

Thanks, Jon!

|

|

|

|

Post by rumbleseat on Mar 15, 2016 17:01:46 GMT

That is one sick and clean looking Exocet. Nice work!

|

|

|

|

Post by jon on Apr 6, 2016 3:01:51 GMT

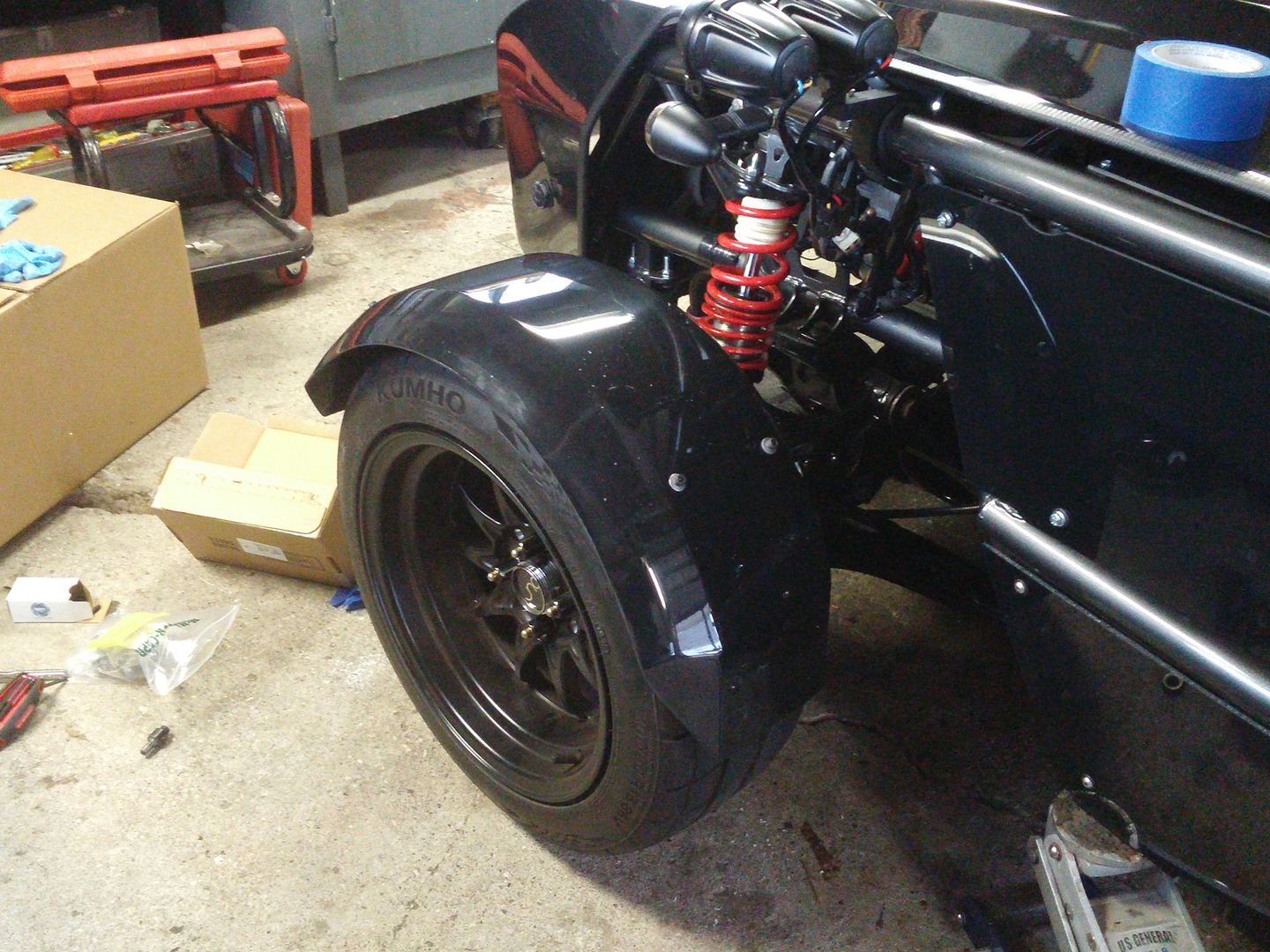

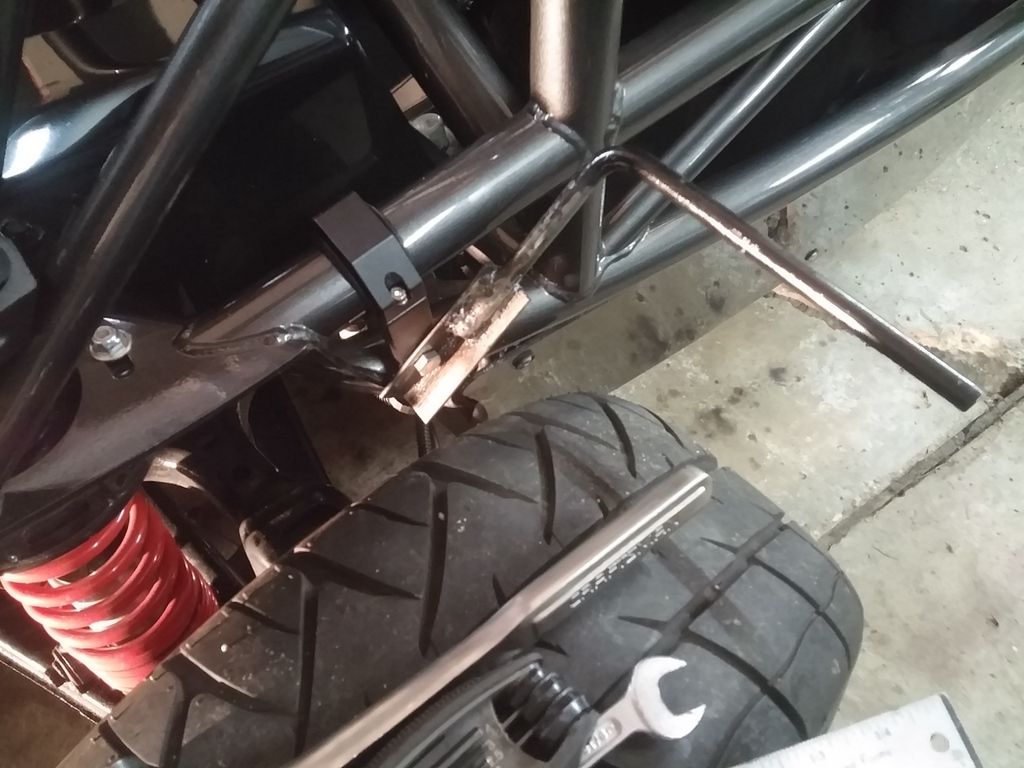

My local track says I needed fenders to not be an open wheel car, so I am in the process of adding the fenders. Fronts were easy, however, I admit it is difficult to get the fenders to all sit in the exact same way.  My rear knuckles do not have the nub for mounting as it is an early NA donor. After a lot of debate, I went with fixed rear fenders . I am giving them 4" of clearance from the tire at rest. I used roll bar clamps to attach to the frame and modified the fender stays.    |

|