|

|

Post by greg on Feb 2, 2016 13:12:14 GMT

Love it!

|

|

|

|

Post by einy on Feb 2, 2016 17:48:31 GMT

I dig the carbon dash panel, Jon. What clamps did you use to bolt it to the cross bar? I have a similar use in mind on mine ...

|

|

|

|

Post by jon on Feb 2, 2016 18:00:49 GMT

I 3d printed some P clips. I am going to change them a bit to fit better, and add some black cap head bolts.

If you ever need any mounts like that, let me know, I can print up a set no prob.

My wiring is now completely covered up. I am pretty happy with the look. Minus some never ending things to tweak, I am considering the car 100% done now (but it is never really done!).

|

|

|

|

Post by zeitgeist on Feb 2, 2016 21:37:27 GMT

Congrats Jon. The dash panel looks good even with silver screw heads. There are always details and changes. Isn't that the fun part?

|

|

|

|

Post by steadfast on Feb 2, 2016 22:33:49 GMT

Where was the carbon panel sourced from?

|

|

|

|

Post by jon on Feb 2, 2016 23:47:19 GMT

www.rockwestcomposites.com/plates-panels-angles/404-410-groupCarbon aint cheap anywhere. I was struggling to find a plate of approximately the right size. I got a 6 X 24 x 0.115 sheet, which is very sturdy. The weave looks pretty good, but I was disappointed in how they cut it from the factory. Edges were rough and not exactly straight. Took a little bit of sanding with a block to get it square. I ended up shortening mine to 19" long to fit where I needed it. Alternatively, one could use some cheap plastic and cover with vinyl carbon wrap. Might look just as good.

|

|

|

|

Post by einy on Feb 3, 2016 13:26:32 GMT

Jon - do you have (or can you take) any pics you can post of how exactly your fender mounts bolted up to the knuckles? On the front, I 'get' how the one with the ring / three holes bolts up to where the dust shield originally was, but am not clear on the other front mount. Same thing on the rear - I get how the one that bolts up to the side of the (unused) ABS sensor boss, but not the other one.

Thanks in advance !!

John

|

|

|

|

Post by jon on Feb 3, 2016 15:07:58 GMT

I have opted for the time to not run fenders.

Turns out, my rear uprights do not have the boss on them to mount the most rear fender mount. Apparently, early Miata's don't have this. I do not see an easy way to rectify that situation without getting new uprights. I just spent a bunch of time putting new bearings in those... no going to redo it.

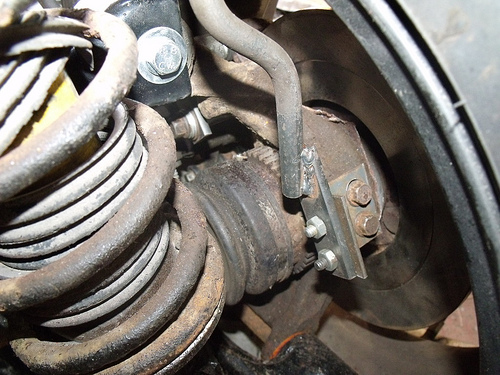

Anyway, to answer your question, the other mounts attach to the top bolt on the brake caliper (both front and rear). Drill a hole in the mount , remove the top caliper bolt, and install. Granted, it is only 1 bolt holding that, so it is not entirely constrained to prevent rotation.

I have been trying to think of ways to mount my rear fender without the boss. I think the only way is to fabricate a bracket that bolts to BOTH caliper mounts and wraps around the upright, providing a location to bolt both fender bars.

I am not decided on how much I want the fenders anyway. Everyone says that they vibrate at speed. I read one account that between rocks hitting them, and stupid people sitting on them at shows, they got destroyed fairly quickly. I go back and forth on which looks better; with or without them.

|

|

|

|

Post by jon on Feb 3, 2016 15:18:30 GMT

I may be getting a small CNC router soon as a gift for myself  It can cut aluminum... maybe I'll make some francy brackets for the fenders with that. |

|

|

|

Post by einy on Feb 4, 2016 12:05:03 GMT

I'm a bit undecided on the fender issue also, based on exactly what you noted above. Then again, small rocks in the face at 60 MPH sort of sting.

|

|

|

|

Post by jon on Feb 4, 2016 13:05:34 GMT

A complete new fender mount i think is necessary to make these work the way we want them. Looking at the knuckles, there are few options for achieving that.

|

|

|

|

Post by thestig on Feb 4, 2016 17:05:06 GMT

I have opted for the time to not run fenders. Turns out, my rear uprights do not have the boss on them to mount the most rear fender mount. Apparently, early Miata's don't have this. I do not see an easy way to rectify that situation without getting new uprights. I just spent a bunch of time putting new bearings in those... no going to redo it.  This is from the build guide on exomotive. make your own bracket. |

|

|

|

Post by jon on Feb 4, 2016 17:11:08 GMT

The holes for that bracket only exist on ABS equipped Miatas, as far as I know. Mine does not have them. There is nothing to attach to at all on that side of the knuckle.

And drilling into the knuckle is a very bad idea, IMO. Welding would also be an undesirable solution.

|

|

|

|

Post by ImprobableConstruct on Feb 4, 2016 17:25:20 GMT

I may be getting a small CNC router soon as a gift for myself  It can cut aluminum... maybe I'll make some francy brackets for the fenders with that. What model are you looking at? Shapeoko 3? Xcarve? |

|

|

|

Post by jon on Feb 4, 2016 17:33:27 GMT

Yeah, Shapeoko 3 is what I am eyeing. Granted, aluminum is not the best on it... but I think it can do some basic small stuff.

With a CNC router, I will gain conventional subtractive manufacturing to complement my 3d printer additive manufacturing!

|

|