|

|

Post by pocketrocket on Sept 27, 2016 0:33:14 GMT

I am curious about the fitting of the lable for the brake bias. The label states that you must not adjust the bias but what if you find the bias needs adjusting later on to fine tune it? Is the bias tested in any way to meet a standard? How will they know it has been adjusted from the IVA test settings? I have seen builders setting bias before the car is finished which seems crazy. I know my fronts lock up before my rears, I found out recently when hard braking in an event, Ive since reduced front bias fractionally and will see what happens next time I test this. I want the fronts to lock just before and the only way I can see to acheive optimum is to keep testing and tweaking. I think this is one of those silly rules that I just have to go by. My rears lock slightly before the fronts, but I have 450kg over the rear wheels and only 210kg over the front (excluding driver) so the examiner said this is a pass. It was just luck really as I din't adjust the bias bar at all, I just set it as it was out of the box. Regardless of the weights over each axle (that's what the bias is for), the inspector accepts the rears to lock before the front? I'm flabbergasted |

|

|

|

Post by kiwicanfly on Sept 27, 2016 2:11:08 GMT

I am just doing what the examiner told me. He can't re-fail it then. Unfortunately he can. He made a suggestion to solve a problem, if that problem is not solved by his solution then he will be unable to pass you despite what he said previously. Also I doubt you can guarantee to get the same examiner. I am sorry to keep on about this but I honestly think the problem is the size of your spacers which are not giving the support required, the bar he has suggested will do nothing as it is in the wrong plane for the forces applied. Now if you do get the same inspector and he simply looks at the bar or if he tests it and is happy then great. But the time and effort to required add a decent diameter spacer in there is under 15 minutes, then leave the bar on just to keep him happy and you are fine. Also, as pocketrocket implies, you are taking technical advice from a man who passes rear brake lockup due to the weight distribution? |

|

|

|

Post by mawdo81 on Sept 27, 2016 6:53:57 GMT

Sorry but your inspector is wrong. Section 09E on Brake performance, required standard 21 is pretty clear:

All wheels of the rear axle(s) must not lock prior to both wheels of the front axle.

I'd adjust the balance forwards or in an emergency you are effectively going for a handbrake turn...

|

|

|

|

Post by turbosteve on Sept 27, 2016 7:22:47 GMT

Lets say that, when i brought my rocket back from IVA, i tried an emergency stop. Front wheels locked, absolutely no rear lock. Overshot my junction in a big cloud of tyres. Beauty of exo cars, being able to see the wheels lock! Tag came off, pin came out, and adjusted so I would not die. One of my post IVA issues  |

|

|

|

Post by carlyd on Sept 27, 2016 10:05:05 GMT

Whether the inspector is wrong doesn't matter to a point as he chooses to pass or fail my car, so I am not going to start arguing with him and pi$$ him off.

The inspector only re-tests the failed points - like an MOT re-test so the brakes have already passed.

I will be doing my own checks when it's road legal and as I plan to do some track days so I will be altering brake bias to get it spot on.

The examiner wrote on the failure sheet to brace the brake pedal box which I have done exactly as he has asked.

The spacers have an M8 hole, the bolt is an M8 so there is no 'flappiness' in there.

The spacers can't be any smaller (They are 10mm) as the pedals won't fit with a smaller spacer.

As everyone else has done this without the brace bar I am not concerned for safety and that is my main issue so long as I get the pass.

|

|

|

|

Post by Stiggy on Sept 27, 2016 14:15:18 GMT

the diagonal brace for the pedal brackets should be made from 6mm x 20mm and the top tube should be 2.5 mm wall thickness.

|

|

|

|

Post by carlyd on Sept 27, 2016 15:23:20 GMT

The short diagonal brace was on one side only and should be 6x20mm. The examiner saw this brace and suggested that there should have been one on the other side too (there isn't). Maybe a mod for the Rocket 2? |

|

|

|

Post by kiwicanfly on Sept 27, 2016 19:05:24 GMT

Ok one last try. I accept your desire to do exactly what has been asked of you. However is there any possibility that when he said to put a brace bar on he meant BETWEEN the pedal box and mounts? This would stop twisting of the mounts and provide lateral bracing as well. Although I (clearly) believe this can be done with large diameter spacers alone a brace such as this would be even stronger. A piece of aluminium 25mm wide by 10mm thick (or whatever spacing you need) would be spot on. One for each pair of bolts and in same orientation as you've show. Honestly  not cause you grief. On the subject of mods in this area for future models, putting the mounts lower to allow the box to bolt without spacers would be a good plan. |

|

|

|

Post by pocketrocket on Sept 28, 2016 0:54:38 GMT

Am I the only one that is concerned that this inspector is allowed to inspect anything more than a wheel barrow.   Although it might be an unusual request, is there any chance you could find a different inspector? |

|

|

|

Post by turbosteve on Sept 28, 2016 7:18:35 GMT

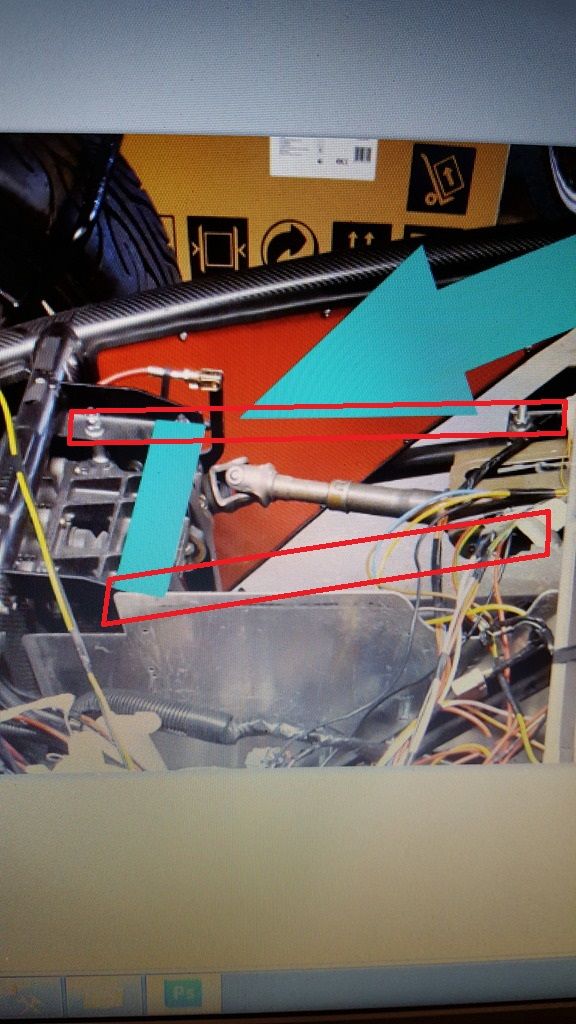

Am I the only one that is concerned that this inspector is allowed to inspect anything more than a wheel barrow.   Although it might be an unusual request, is there any chance you could find a different inspector? The inspector can choose to question the structural integrity of the vehicle build if he/she wishes. And without an engineering degree. I have been quizzed on past build about wishbone tubing, roll bar welding, seat belt load paths etc. I had the answers and knowledge to get past those points, and one robin hood kit required new 3mm angle sections joining the axle mounts, to the upper roll bar. It was a monocoque chassis. I would like you to run 2 x pieces of angle, from the 4 steering column bolts, to the 4 pedal box bolts. Say 3mm thick. This would remove any flex from the pedal box, to the column. The bar you have made to me, serves no purpose in increasing structure. Maybe you have mis understood the inspector? |

|

|

|

Post by turbosteve on Sept 28, 2016 7:27:46 GMT

I would also cross brace it, some triangulation. |

|

|

|

Post by carlyd on Sept 28, 2016 8:28:27 GMT

Am I the only one that is concerned that this inspector is allowed to inspect anything more than a wheel barrow.   Although it might be an unusual request, is there any chance you could find a different inspector? The inspector can choose to question the structural integrity of the vehicle build if he/she wishes. And without an engineering degree. I have been quizzed on past build about wishbone tubing, roll bar welding, seat belt load paths etc. I had the answers and knowledge to get past those points, and one robin hood kit required new 3mm angle sections joining the axle mounts, to the upper roll bar. It was a monocoque chassis. I would like you to run 2 x pieces of angle, from the 4 steering column bolts, to the 4 pedal box bolts. Say 3mm thick. This would remove any flex from the pedal box, to the column. The bar you have made to me, serves no purpose in increasing structure. Maybe you have mis understood the inspector? Kiwi I agree that the brace bar does nothing, I don't disagree with anything said here at all and I completely understand your points. I personally am happy that the flexing is very minimal and was only present (barely) when the guy had as much pressure as he could possibly manage in the brake pedal, therefore and I am comfortable driving the car as is. I am sure the wheels would lock way before I could ever put that amount of pressure on the brake pedal. The examiner has asked me to do things that no one else with a Rocket has done for IVA so I am following his instructions to the letter. Steve, the examiner outlined exactly where the brace bar should go and the material I should use for this. I have done exactly as instructed, I even plan to send him the photo via email before I go back for retest. The fact that no other Rocket build has had to do this says to me that it's complete rubbish and that it's not required, but will make him feel better about it. By the way there are two instructors at Nottingham and they were both looking over my car so no chance of a different examiner. I am now trying to find a solution for the seat / seat belt problem. Basically my seat belts are bolted to the chassis under the seats (as everyone's are). As the belt wraps around the seat he is worried that the seat will smash in a crash and give the seat belt slack. Also the lap adjustment straps are too close to the anchor points so the inside of the seat which is next to the tunnel cannot be adjusted. How have others got around this? or is it just me again? |

|

|

|

Post by carlyd on Sept 28, 2016 11:30:39 GMT

Basically my seat belts are bolted to the chassis under the seats (as everyone's are). As the belt wraps around the seat he is worried that the seat will smash in a crash and give the seat belt slack. Also the lap adjustment straps are too close to the anchor points so the inside of the seat which is next to the tunnel cannot be adjusted. How have others got around this? or is it just me again? OK here is the seat belt problem. I think the main issue is that the lap belt adjusters are too close to the mounting plates (see pic)  This is how the look in the Rocket, the adjusters are under the seat.  The only solution I can think of is buying new belts. That's just more expense though  |

|

|

|

Post by mawdo81 on Sept 28, 2016 12:32:00 GMT

Think you're right, but you should be able to re-sell these to someone where they're more suitable. Or can you exchange? I fear anything else will either not pass or not be practical in the real world.

|

|

|

|

Post by carlyd on Sept 28, 2016 14:41:13 GMT

Of all the failure points this one bothered me the most as it's obviously life or death in a crash. So I have bought x2 Sabelt 4 point harness. I have also cut my seats as the belts would still wrap about the seats as (I have wider than normal seats). So now the belts will go through the seat meaning the seal will not hinder the support of the belts in a crash. This is from the underside and they need some tidy up work but this should do the trick.  |

|