|

|

Post by pincherrn on Jan 27, 2013 13:59:05 GMT

I think Rich (stubbers) was looking at doing that too but not sure if he did in the end. There are a few comments on his build thread about it.

Colin

|

|

|

|

Post by jgilbert on Jan 27, 2013 20:56:28 GMT

Ok read Rich's thread, I think he was mounting the fuel lines on the PPF. "It's alright just my clips arnt as mount friendly as I'd hoped as there very big!!!

Just wondered if there was any major problem with mounting along the ppf. the brake lines will be mounted to the chassis though. All help appreciated

Rich"

My thinking was as shown below.  If the PPF is good enough for the electrical loom then the brake line shouldn't be a problem, Stainless tee joint on sub frame and continuous lines to the brake callipers. Can any spot a problem? Thanks |

|

|

|

Post by gnc on Jan 27, 2013 21:37:34 GMT

Congratulations on the build so far, it's looking superb.

We've still got to strip our subframes but thoughts as to routing the brake and fuel lines are already in progress.

Fastening along the ppf for both sets of lines doesn't look like it will be a problem. We considered if drilling the ppf might weaken it in any way but Mazda have already done this for the wiring clips so can't see any reason why not.

It sure would make a lot of sense to be able to do this with so much access available.

|

|

stubbers

Senior

Exocet Number 306

Exocet Number 306

Posts: 478

|

Post by stubbers on Jan 27, 2013 23:54:46 GMT

Yeah my electrical and fuel lines are on the ppf and then brakeline is on the Exocet chassis. Plently of room for clips on the ppf, I used plumbing fittings for the rubber fuel hose, worked a treat  Rich |

|

|

|

Post by Kevin Patrick on Jan 28, 2013 15:55:38 GMT

Can any spot a problem? Thanks Looks great to me - we've sold a few full stainless steel flexible brake line kits and that is basically exactly what we do. |

|

|

|

Post by jgilbert on Jan 28, 2013 22:01:48 GMT

Can any spot a problem? Thanks Looks great to me - we've sold a few full stainless steel flexible brake line kits and that is basically exactly what we do. Kevin thank you for the reply, just looking at the PPF again, how have you supported the brake line from where it leaves the engine bay to the start of the PPF? I guess you then have to rely on the Exocet frame for fixing positions. I think its recommended that a flexible brake line is supported every 8 inches. It must be 2 feet between the engine bay and start of the PPF. Thanks |

|

|

|

Post by Kevin Patrick on Jan 28, 2013 22:36:11 GMT

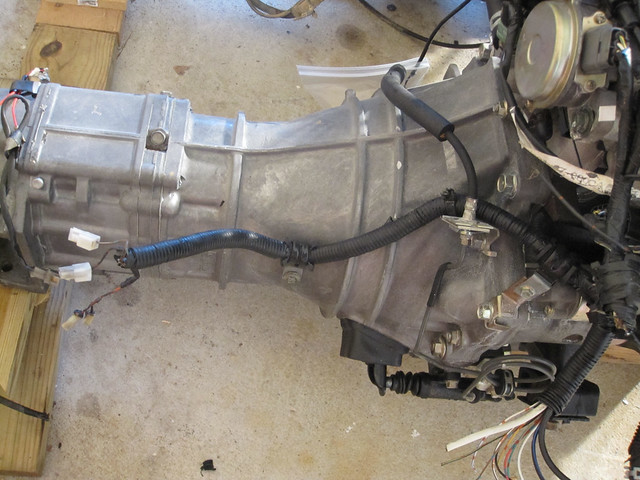

I don't think I have a good photo of it, but it basically ties in to the vertical tube at the bulkhead. For that particular build, the wiring harness PPF clips were bad, so I installed rivnuts in the existing PPF holes and ran two P-clips - one for the harness and one for the brake line. I also did this with the existing harness p-clip mount on the side of the transmission (center of this photo):  I think that left about a foot between the last transmission p-clip and the front bulkhead p-clip. When I was mounting it, my main concern was to ensure that even if a motor mount broke (or some other catastrophe) then the resulting engine/trans movement would not be enough to put stress on the brake line and stretch or break it. |

|

|

|

Post by jgilbert on Jan 28, 2013 22:51:03 GMT

Kevin thanks,

Very helpful.

|

|

|

|

Post by jgilbert on Feb 3, 2013 22:25:05 GMT

Update on progress this weekend. So I've been struggling with removing the rear hubs from the drive shafts. In the end I bit the bullet and decided I would have to leave them assembled and work around this to remove the brake cover plate. So I purchased a Ryobi 'Dremel' tool and some metal cutting discs. Amazing bit of kit, definitely worth the £29 it cost. Was able to remove one of the rear brake backing plates with ease.  Then got on with cleaning and painting the half shaft. Also mounted the diff in the sub frame so next job is to replace the diff/shaft seals and refit the drive shaft.   Finally, got the Cam cover painted and fitted.  Adjustable droplinks also arrived.  |

|

|

|

Post by welshy1 on Feb 3, 2013 22:31:09 GMT

Looks good liking the adjustable drop links.

|

|

|

|

Post by mathew on Feb 3, 2013 22:35:50 GMT

Have you left the brake backing plate as it is in the photo? If so, that small piece thats left will pull off with enough force.

|

|

|

|

Post by jgilbert on Feb 3, 2013 22:38:37 GMT

Have you left the brake backing plate as it is in the photo? If so, that small piece thats left will pull off with enough force. No mate, photos not very clear, but I slit it with the Dremel and pulled it off like you said. |

|

|

|

Post by jgilbert on Feb 12, 2013 22:37:34 GMT

So finally got the PPF all back together tonight ;D Painted the drive shafts over the weekend and refitted. So if the PPF had wheels on I'm back to a rolling chassis. Spooky two months and 1 day ago from when we lifted the body off. Haven't tightened the PPF gearbox and diff bolts up yet as I assume this will give me a bit of adjustment for fitting the frame? comments welcome.   Also fitted the same adjustable drop links as the front.  So next job is think about the kit  , and continue to add bits back onto the engine. |

|

|

|

Post by jgilbert on Feb 20, 2013 22:53:12 GMT

Fun day today  Thanks Stuart.  |

|

|

|

Post by jgilbert on Feb 24, 2013 21:32:33 GMT

Not much achieved this weekend. However I did mount the front to rear brake line and fuel lines. Unconventionally, I used the PPF to mount these. The next photo should show this. The brake line is riveted in position and the fuel line drilled and taped. The screws for the fuel line were then installed with thread lock.  This also meant welding a tab on the rear subframe for the brake tee, and then making a bracket for the drivers side in order to secure the drivers side brake line where the original tee would be. You can see the new bracket in the next photo.  |

|