|

|

Post by Fin on Sept 1, 2016 16:34:06 GMT

Mistakenly believed that replacing the brake seals would be an easy task. Putting the main piston seal on is like trying to open and put on a condom when your hands are covered in baby oil!

|

|

|

|

Post by johnp on Sept 1, 2016 16:43:53 GMT

Teeth are handy at that stage of the game, or an extra pair of hands. We are talking cars here?

|

|

|

|

Post by Fin on Sept 1, 2016 17:51:53 GMT

Teeth are handy at that stage of the game, or an extra pair of hands. We are talking cars here? Well, the extra hands threw me, but yes! |

|

|

|

Post by Fin on Sept 3, 2016 13:55:41 GMT

First new replacement brake caliper dust seal split when trying to put it on using the inflate method. Struggled with the second caliper, trying to both inflate the dust seal, and also lifting it over the piston, but a waste of 90 minutes. Finally, the light went on, and I checked against the original, which slipped back on without effort. Supplier must have sent wrong set, or at least that's my story, and I'm sticking to it!

|

|

|

|

Post by Fin on Sept 6, 2016 18:37:55 GMT

Wife's away for a week, so clear blue water to make progress, with no excuses, so, being a sunny Sunday, we put the gazebo up for a relaxing afternoon. Soon decided we'd better use it as a shelter from the wind in order to get some painting done. Bit out of sequence, but fancied achieving something, and at the same time experimenting with some underseal spray pain on the sub-frame. The test panel came up with a lovely textured & shiny jet black, but it soon dried to a sooty, rubbery black, but it will do.   Despite it being well ventilated, a face-mask is on the way. Tuesday saw an attack on the control arm bushings. If I can't get these out, I can't get them blasted and powder coated in orange, so it'd have to be rust-remover and de-greaser, and to be honest, the rust-remover hasn't impressed. So, didn't fancy a rubber BBQ, and don't have oxy-acetelene, so made a little bush removal tool that might help folk. Dismantled a scissor-jack and took the screw-bar and twin (red) ends off - one threaded and one loose by the screw winding head. With the loose red end inserted over the screwbar and next to the winding handle, I threaded a long 29mm socket facing inwards. I then threaded the bar through the centre of the offending bushing, and threaded a 40mm socket also facing inwards, followed by the red threaded winder bar from the jack. The 29mm socket will push the bush, and the 40mm is big enough to overlap the bush and sit on the metal of the arm, and deep enough to receive the bushing as it is pressed through. Prior to inserting, I trimmed to exterior lip of the bush and sprayed WD-40.    Whole process took less than a minute per bush, and might be clearer here. Happened to have a spare scissor jack, so just cost me £12 for the 40mm socket, but you could probably buy suitable screwbar somewhere. |

|

|

|

Post by Fin on Sept 6, 2016 19:01:31 GMT

First new replacement brake caliper dust seal split when trying to put it on using the inflate method. Struggled with the second caliper, trying to both inflate the dust seal, and also lifting it over the piston, but a waste of 90 minutes. Finally, the light went on, and I checked against the original, which slipped back on without effort. Supplier must have sent wrong set, or at least that's my story, and I'm sticking to it! Apparently, there are two different sizes - 51 & 54mm. You guessed it  |

|

|

|

Post by Fin on Sept 8, 2016 8:07:48 GMT

Finished off popping the bushings out, only to discover Mazda had one further trick up their oriental sleeves. The inner diameter of the crush tubes on the lower rear control arm bushings is smaller at 10mm, so have to buy some smaller diameter threaded bar and re-make. Hopefully get a price for shot-blasting and powder coating tomorrow if they can match the "Tangerine" colour of the body. Finally, finished off the gearbox.   Shame it won't get seen! |

|

|

|

Post by Fin on Sept 9, 2016 18:26:40 GMT

Finished spraying rear sub-frame, but gave up on the idea of painting the diff as it's just too dirty, even after de-greaser & a pressure-wash. Likewise, the prospect of painting the engine block, but will clean it & the sump as best as I can. Whipped the cam cover off to go for powder-coating on Monday, along with most of the suspension.  Need some new castle nuts, a couple of replacement seals for the ball joints and some new bolts, and might be in a position to start putting things together for a change. |

|

|

|

Post by Fin on Sept 12, 2016 11:12:17 GMT

Better, but I think they need to be re-done in orange!  |

|

|

|

Post by Fin on Sept 14, 2016 16:18:46 GMT

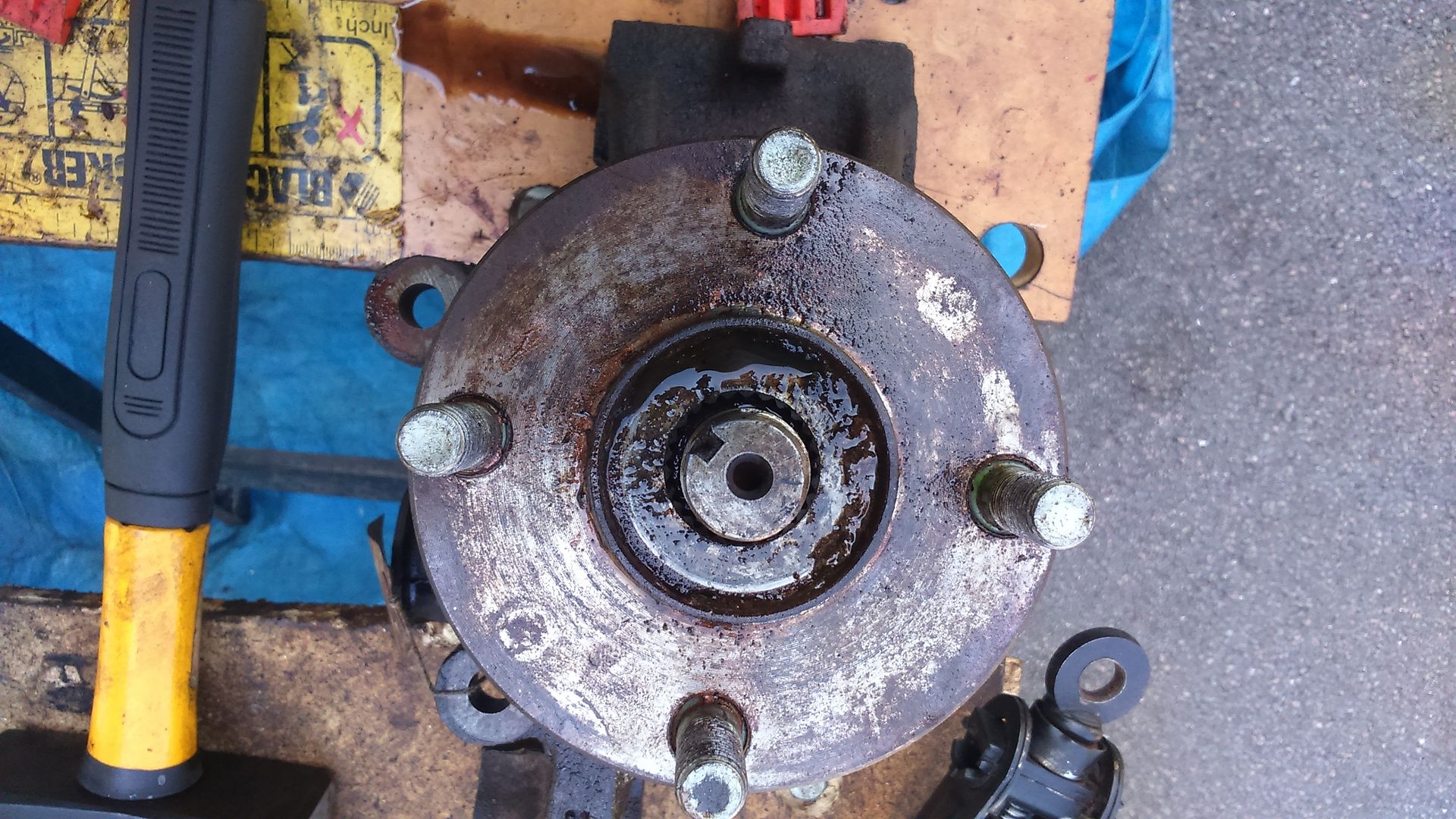

HELP!! Cannot remove the nearside drive/half-shaft spline from the hub/knuckle. Have drowned it in a 50/50 mix of ATF and Acetone and left it overnight, applied heat and generous encouragement from a 3lb hammer, rubbed with a wire brush, and pryed it with a crowbar. Finally, went to Machine Mart and bought a hub removal tool only for the tool itself to break after the impact wrench was applied!  Any thoughts welcomed |

|

|

|

Post by p5curly on Sept 14, 2016 18:12:18 GMT

Clean it up with drive shaft still attached that's what I did with ours

|

|

|

|

Post by Fin on Sept 14, 2016 18:39:39 GMT

That's the "fall-back" position if I can't get it off to have it powder-coated.

|

|

|

|

Post by p5curly on Sept 14, 2016 19:17:26 GMT

Our rear near side never came apart so we just cleaned and greased it and it still works I had forgotten about it till I read your post

|

|

|

|

Post by tojeiro on Sept 15, 2016 23:41:21 GMT

Same here, put 12t of pressure on it in my press then got scared the hub might crack so just cleaned it up with shaft still in. Common problem, I have seen one case where a guy had to cut the hub in half to get the shaft out. The weirdest thing is that the other side of mine just slid of after tap with rubber mallet.

|

|

|

|

Post by Fin on Sept 16, 2016 7:52:19 GMT

The weirdest thing is that the other side of mine just slid of after tap with rubber mallet. That's adding insult to injury  Last chance today, then it's a scrub and Hammerite for the hubs/knuckles. Hate being defeated by an inanimate lump of metal. |

|