|

|

Post by ImprobableConstruct on Feb 7, 2015 2:04:46 GMT

I finally received my backordered E brake cables from Flyin Miata but the bracket on the trans tunnel is too thick for the adapter brackets they sent. What have you guys done to mount the E brake cables? The new cable are also about 6" longer so that should help with the routing.

|

|

|

|

Post by lhintze on Feb 7, 2015 2:12:27 GMT

Mine were sent out today, I will take a look and see what I get. I noticed the cables seemed a bit long too.

FM refused to cover shipping on the small backordered parts too which pissed me off. Even after the LBBK and coilovers they wouldnt budge.

|

|

|

|

Post by einy on Feb 7, 2015 19:47:42 GMT

Is there a reason one cannot re-use the stock e-brake cable? Or, did you just not have a good set to re-use? Or are these special for your particular setup?

|

|

|

|

Post by greg on Feb 7, 2015 20:03:13 GMT

The new FM brakes need the NC miata brake cables.

|

|

|

|

Post by ImprobableConstruct on Feb 20, 2015 1:46:08 GMT

Sorry I haven't had any updates in a while. I have been working on the car on and off, mostly getting a few minutes here and there. But, I finally got the rest of the brake lines and the fuel line run and secured.  I also finally got around to mounting the passenger side firewall and the transmission tunnel.  I also ran the hand brake and cables.  Its just about time to start the wiring. I labeled everything so that's not going to be a problem but there are going to be a ton of wires to strip out. I plan to hook it all up and get it running before I tear into the wiring harness. |

|

montgom

Full

Love Exocet

Love Exocet

Posts: 274

|

Post by montgom on Feb 20, 2015 1:53:39 GMT

You do very good work.

Robert

|

|

|

|

Post by lhintze on Feb 20, 2015 2:06:08 GMT

I was starting to wonder if you were gonna give us any more updates lol. Car looks good! I am also going to screw my tranny cover down for the time being, just it case it needs to be removed. Wiring is fun, print off the the diagram and it tells you everything you need to know.

|

|

|

|

Post by ImprobableConstruct on Feb 23, 2015 14:52:52 GMT

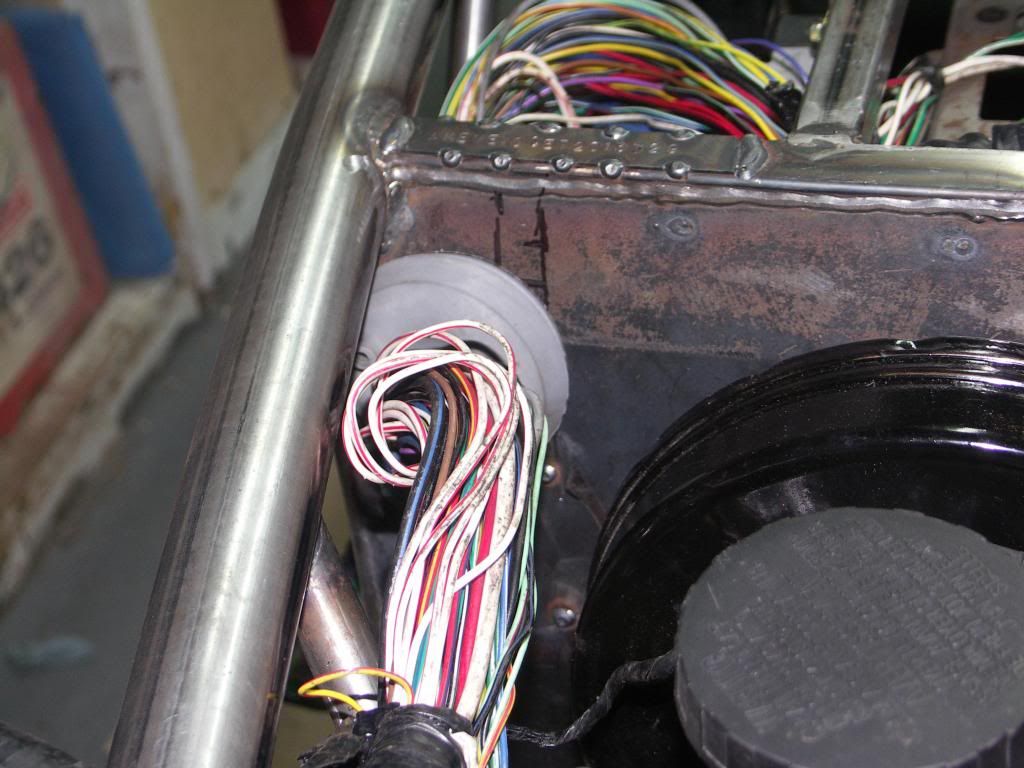

Well I started in on the wiring...  What a mess. I want to start the car before I start cutting wires so I am just working on layout and routing. I haven't bled the brakes or added coolant yet so I can still easily move or unhook things if I have conflicts with the wires. |

|

|

|

Post by lhintze on Feb 23, 2015 15:30:52 GMT

I am 99% done the wiring and will be glad when its 100% done lol. Couple tips I learned along the way:

-print out the wiring diagram, all 34 or so pages, everything is there that you will need.

-cut all the tape and guarding off the harness before you start cutting out wires

-take your time and start the car to be sure nothing major was removed.

-keep the hazard and dimmer switch plugged in, lights won't work if not plugged in

-it seems like I removed half the wires, there is nothing there I am not using now

I'll post pics in my thread this week, I relocated all the necessary relays to the wiring tray as well as ran all my wires down the tranny tunnel (wires for the fuel pump, rear O2 sensor, and rear lights). I had to lengthen these all about 48", every wire I lengthened or shortened was soldered back together. I also plan to notch the pass side firewall piece to run my wires into the tray, I won't have any wires running over the tubes from the engine compartment.

Good luck!

|

|

|

|

Post by lhintze on Feb 23, 2015 15:34:15 GMT

I just saw your pass side firewall was already installed, it will take a big hole to feet the connectors thru now.

|

|

|

|

Post by ImprobableConstruct on Feb 23, 2015 16:28:08 GMT

I did this for the engine harness:  and I planned to either cut this grommet in too or remove the grommet and run the wires over the top bar.  |

|

|

|

Post by lhintze on Feb 23, 2015 18:07:53 GMT

Nice, looks very good! I used the hole for the steering shaft to run the wires for the driver side to the headlights/fan. There was plenty of clearance with the hole thats already there.

|

|

|

|

Post by greg on Feb 23, 2015 21:10:57 GMT

Looks like you guys had the same idea I did. What size hole did you cut for the grommet? Guessing you cut two circular holes with a hole saw then finished with a grinder or dremel?

|

|

|

|

Post by ImprobableConstruct on Feb 23, 2015 21:39:48 GMT

Looks like you guys had the same idea I did. What size hole did you cut for the grommet? Guessing you cut two circular holes with a hole saw then finished with a grinder or dremel? I actually used AutoCAD to draw a 47x68 mm rectangle. I then filleted the corners with a 23mm radius to make a template for the hole. I then used an air nibbler to cut it out. |

|

|

|

Post by jgilbert on Feb 23, 2015 23:26:40 GMT

I did this for the engine harness:  and I planned to either cut this grommet in too or remove the grommet and run the wires over the top bar.  Hi you can install the loom using to large round grommet, It requires about a 2 1/4" hole saw from memory. I did this on both sides of my car. This picture shows the drivers side hole. But a word of warning - on the drivers side be carefully not to drill the grommet hole where the accelerator cable needs to pass through. I did this the first time, you can see the welded up hole beneath the grommet hole.  and from the engine side a nice neat cable entry. Lots more photos in my blog.  |

|