|

|

Post by hightower on Nov 26, 2014 20:50:47 GMT

|

|

|

|

Post by kiwicanfly on Nov 26, 2014 20:59:04 GMT

Jeez that is major.

Hope they have put something inside the tubing to spread the load on the welds.

Reckon you should add a vertical under the roll bar down to lower chassis rail as well.

Appreciate it is still a work in progress though so will be interesting to see the finished result.

|

|

|

|

Post by hightower on Nov 26, 2014 21:04:36 GMT

Yea I'd like a couple of supports in too just to stop any twisting under strain. Not that I'm an engineer haha

|

|

|

|

Post by kiwicanfly on Nov 26, 2014 23:22:39 GMT

Something else not considered also is the COR, I bet that does not fit now ..........  |

|

|

|

Post by Stiggy on Nov 28, 2014 17:19:39 GMT

I always encourage innovation but in this case if the tube size of the extensions does not match perfectly and it is clear that joins in the most important part of the chassis have been made then the IVA inspector is unlikely to accept it. This area is where the main mass is loaded and the main forces are applied. Sorry to be the voice of bad news but I would not be doing my job properly if I did not mention this. Please read the following as constructive. Internal sleeves and exact match external tube is the only way. Seams and puddle welded to secure. Introduction of diagonal bracing to the sides of the engine bay would also help.

I suggest that the rear stays are cut out and replaced, joining at the back of the engine bay as they were. You may also consider a brace down from the rear stays to the top of the shock mount, this is how I did the Mevabusa but without full FEA it would be wrong for me to advise any further. At the moment the alterations do concern me but I am sure it will all be engineer checked and tested for squareness and structural integrity later. Good luck with the project. It should look cool with the extra long wheelbase.

|

|

|

|

Post by deanohonda on Nov 28, 2014 20:33:04 GMT

Hi jason just been thinking u could come up with ur own original name for it & not borrow someone else's snappy name?

maybe rocket Type l

lol ;-)

|

|

|

|

Post by hightower on Nov 28, 2014 21:57:31 GMT

Thanks for the advice and pointers Stuart I have forwarded the message to DANNY at Mk motorsport so that he can do the relavant alterations to make that car legal and roadworthy. As I said before I'm far from being an engineer so I rely on the comments and observations of people a lot more clued up than myself to aid me in the build.

I'll take photo's as work is done.

|

|

|

|

Post by hightower on Dec 2, 2014 21:25:08 GMT

Bit more of an update today fuel tank started with original zx 10 pump in the bottom   |

|

|

|

Post by hightower on Dec 2, 2014 21:26:26 GMT

My beautiful sequential gear lever with push pull rigud cable.   |

|

|

|

Post by hightower on Dec 2, 2014 21:27:47 GMT

Wilwood hydraulic clutch conversion too.  |

|

|

|

Post by hightower on Dec 2, 2014 21:30:18 GMT

|

|

|

|

Post by hightower on Dec 5, 2014 20:36:55 GMT

|

|

|

|

Post by hightower on Dec 5, 2014 20:38:22 GMT

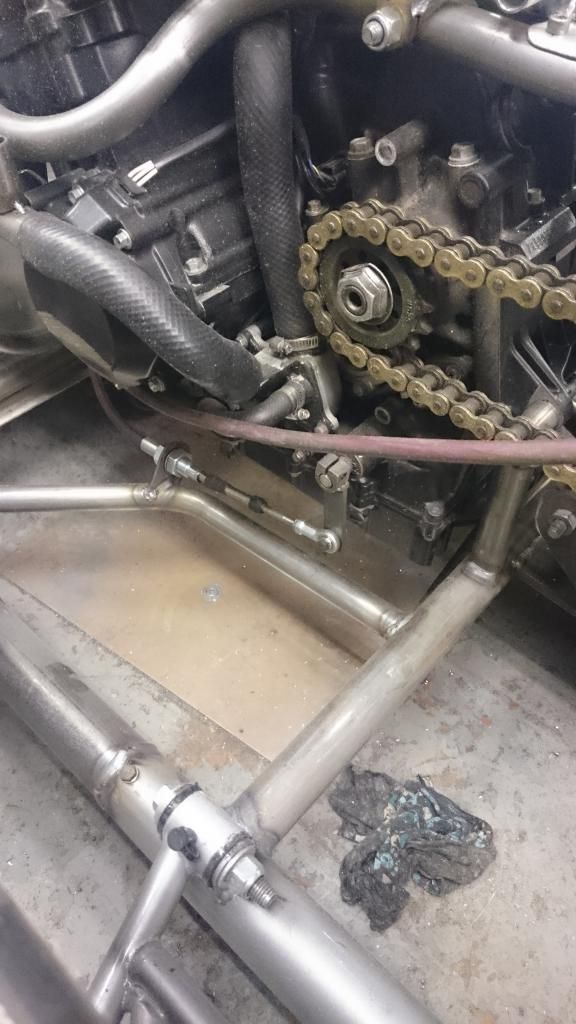

Couple of photos of new rear chassis with a cost of paint , will all be re powder coated in next 12-18 months after a few miles under my belt to iron out any problems and inprovenents .engine and diff getting cleaned up ready for fitting and some powder coating to engine cradle .   |

|

|

|

Post by hightower on Dec 10, 2014 7:52:57 GMT

|

|

|

|

Post by hightower on Dec 12, 2014 20:57:39 GMT

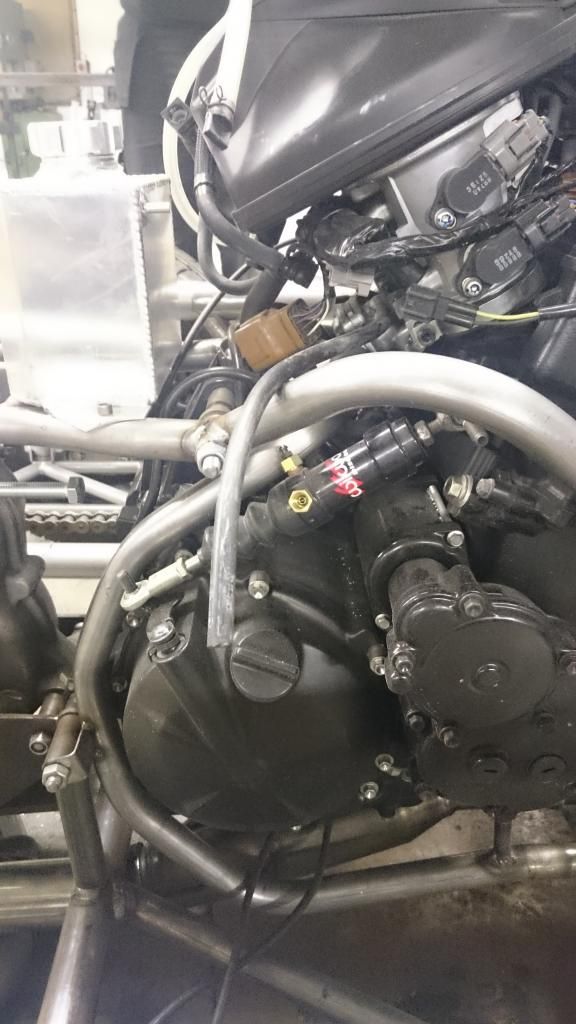

New rear brace bars fitted to take rear engine panel adjusted at the top so engine cover fits in one.  |

|