|

|

Post by donboy1983 on May 6, 2014 21:25:08 GMT

I undone the bolt as I was struggling to get enough movement to get it off the diff so I thought it would make life easier, and it did Well I'm happy now that I know that the top captives can come out without causing a problem. This is the bit I had seen that said they can't come loose but they look like a slightly different type of nut.  next job will be to get the shafts out now I know what part I need to hit :-) thanks for the info. |

|

|

|

Post by jwagner on May 7, 2014 4:24:09 GMT

The shafts do just pop out of the diff with a little persuading. My son was on one side of the shaft with a decent sized crowbar and I was on the other with a medium prybar and they did just finally give and slide out. It wasn't so much the amount of force needed to pull it as it was awkward to get solid leverage with the diff sitting on the floor (just like yours).

I would be concerned about the loose captive nuts. They will go back in, but I've heard that if they're not held in tightly they may turn in the PPF if you try to take it off again, making it nearly impossible to get the PPF off the diff.

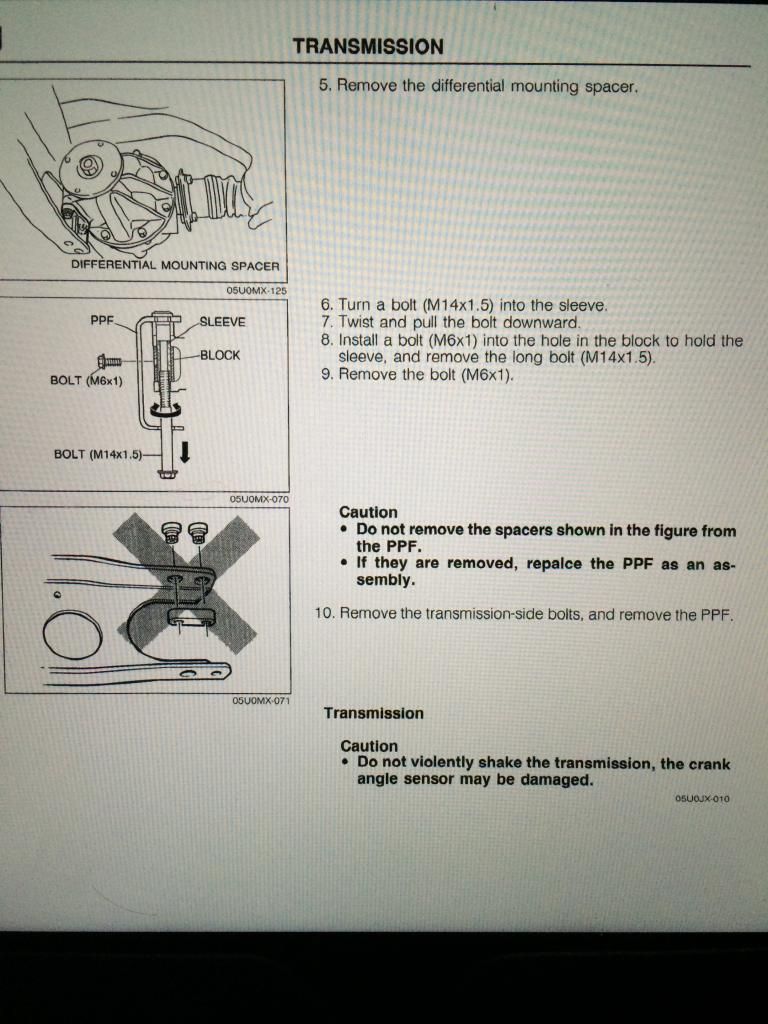

Looks like you've also got that nasty sleeve still in place on the bottom of the PPF. We did pull that before the PPF came off, it took a lot of beating with a chisel and a large hammer. You can probably get it out a little easier with the PPF off.

The hubs are a pain to get off the other end of the axle. One came off pretty readily with our shiny new 3 jaw puller. The second broke an arm off the puller and it's still on the axle. Need to research ways to get it off, but I'm thinking a trip to a shop with a press might be in order.

|

|

|

|

Post by gwnwar on May 7, 2014 5:07:32 GMT

If you do take the captive nuts of the top of PPF and reuse them stake them in place real good so they don't turn..

|

|

|

|

Post by R2S on May 7, 2014 7:22:27 GMT

Looks like you got the bolts out easier than i did (Derbyshire Replicar), i destroyed the cast spacer as the inner sleeve welded itself to the bolt! As for the captive nuts coming out if the knurled (interference) edge has been smoothed won't there be a problem getting the right torque when you rebuild (I have the same problem by the way as my nut was pushed out by the bolt which was being held in by the internal sleeve)?

As for the drive shafts i used a small builders crow bar and placed the straight end in between the diff and the ends of the shaft, one short sharp pull and shaft popped out.

As for the hub end i have only had a quick go at releasing (bolts were loosened before car dismantled so no problem there) with a puller and no joy so rather than destroy anything (the lesson learned from my ppf experience) i've put that off for a rainy day.

Good luck with the build.

|

|

|

|

Post by donboy1983 on May 7, 2014 19:20:45 GMT

So what options do I have to secure the nuts back in place? Can I weld them or drill a hole in the dome flange and stick a bolt through to stop it spinning on the PPF.? Any ideas?

|

|

|

|

Post by R2S on May 7, 2014 21:54:58 GMT

First check if the splines are still in tact, if they are then i'd simply press the captive nut back in place using a G clamp when you come to rebuild. If the splines are damaged you could use something like molecular metal (two part compound) and 'glue' it in place, final option might be to drill a small hole through the bolt flange and ppf and use a carbon steel metal dowel (ebay) to plug.

|

|

|

|

Post by gwnwar on May 7, 2014 22:12:41 GMT

Hammer and punch and stake it 4 or 5 places around nut to PPF..

Clean all rust off bolt and in and outside of sleeve and were it sits..need sleeve to move up/down.. coat both with never seize like for spark plugs..

|

|

|

|

Post by donboy1983 on Jun 3, 2014 22:12:16 GMT

So I managed to get back in the workshop tonight and got a fair bit done, I managed to completely strip the front end and get the engine and gear box split so I could get the engine on the stand. I also had to take the fly wheel off which proved quite tricky as it kept spinning, I used my initiative and a small metal tube to wedge between the teeth and the floor and it was as easy as that :-) i have yet to remove the front upper arms from the hub, I guess I will need a ball joint splitter to get these off so will need to buy one tomorrow, Also can I get replacement ball joints for the control arms as on has a split in it. The lower ones look ok but the upper front arm look like the ball joint is part of it.. Next job job will be to burn the bushes out  hopefully it's not to hard. Any tips will be good. here is some pics of tonight's work...     |

|

|

|

Post by danpollitt on Jun 4, 2014 16:36:16 GMT

I burned my bushes out. Started using a blow torch but took a while so ended up firing up the BBQ!! Only took 20 mins to have them all out

|

|

|

|

Post by donboy1983 on Jun 4, 2014 18:01:40 GMT

Sounds like a good plan :-)

|

|

|

|

Post by R2S on Jun 4, 2014 18:40:24 GMT

Must confess i gave up trying to push them out and used a blow lamp, after a few minutes the centre sleeves just fell out and pushing the outer sleeves out with threaded bar was a doddle.

|

|

|

|

Post by donboy1983 on Jun 4, 2014 21:29:24 GMT

How do you get them out with threaded bar?

|

|

|

|

Post by tom on Jun 4, 2014 21:53:19 GMT

I cut any flanges off the bushes with a sharp knife,heated the wishbone around the bush with a blow torch then pressed them out with a vice using a large socket and a bit of steel tube behind to press the bush into. Worked pretty well for me.

|

|

|

|

Post by R2S on Jun 5, 2014 8:02:19 GMT

Threaded bar method is similar to the vice method described above by Tom but instead of a vice you use the largest dia threaded bar you can get through the bush and a large washer slightly smaller than the inner dia of the suspension arm, on the other end you place a tube, or socket, slightly larger than the bush you are pulling out. You can then either lock one end with two nuts or simply tighten up nuts on threaded bar from each end. This method is not so good if bushes are REALLY stuck or the suspension arm edges are corroded as you are relying on the suspension edge to take the force of drawing out the bush. I'd go for vice or hydraulic press as first option; I simply didn't have a vice big enough.

|

|

|

|

Post by gnc on Jun 5, 2014 20:16:22 GMT

I bet your next batch of burgers will taste a little rubbery....

|

|