|

|

Post by mscott on Dec 21, 2016 17:09:04 GMT

Don't Panic Captain Mainwaring !  The Inlet/Outlets may well be 3" but I chose that shaped Inter-Cooler for it's "Narrow Width Packaging" versus a lot of the other Inter-Coolers that are the full width of the Nose-Cone/Radiator. We get close (too bloody close some times) when racing and this looked the safest bet for the job and would allow me to get the pipework as close to the chassis as possible, well that was the thinking at the time.! I simply used 3"-2.5" Silicone Reducers on the I.C. then made all the pipework in 2.5" which is what the Throttle Body opening is.  I'll be fitting the same G19 Manifold and Turbo etc. with Stewart (Freaky Parts) on Sylvia's (his wife) car early next year before the new season so I'm watching your thread to see how it goes for you. Looking really good so far.. Keep up the updates and keep pushing through, it's a hard time of year to get motivated I know. Regards Micky.. |

|

|

|

Post by scooby1929 on Dec 21, 2016 17:31:17 GMT

Don't Panic Captain Mainwaring !  The Inlet/Outlets may well be 3" but I chose that shaped Inter-Cooler for it's "Narrow Width Packaging" versus a lot of the other Inter-Coolers that are the full width of the Nose-Cone/Radiator. We get close (too bloody close some times) when racing and this looked the safest bet for the job and would allow me to get the pipework as close to the chassis as possible, well that was the thinking at the time.! I simply used 3"-2.5" Silicone Reducers on the I.C. then made all the pipework in 2.5" which is what the Throttle Body opening is.  I'll be fitting the same G19 Manifold and Turbo etc. with Stewart (Freaky Parts) on Sylvia's (his wife) car early next year before the new season so I'm watching your thread to see how it goes for you. Looking really good so far.. Keep up the updates and keep pushing through, it's a hard time of year to get motivated I know. Regards Micky.. I will crack on and see if i can get the 3 inch diameter kit to work it just looks awful big I should of got a reducer like you did to 2.5 inch and then used 2.5 pipework. |

|

|

|

Post by welshy1 on Dec 22, 2016 21:03:21 GMT

G19 did a intercooler pipe routing for mine really smart neat install can updated pics or find my last thread on my build for ideas and tips.

|

|

|

|

Post by scooby1929 on Dec 23, 2016 22:19:53 GMT

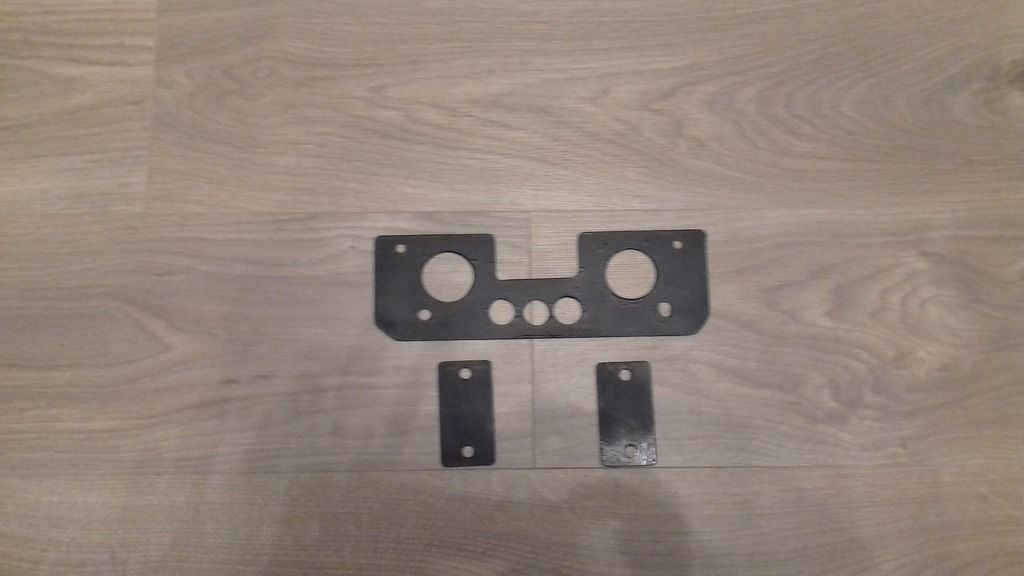

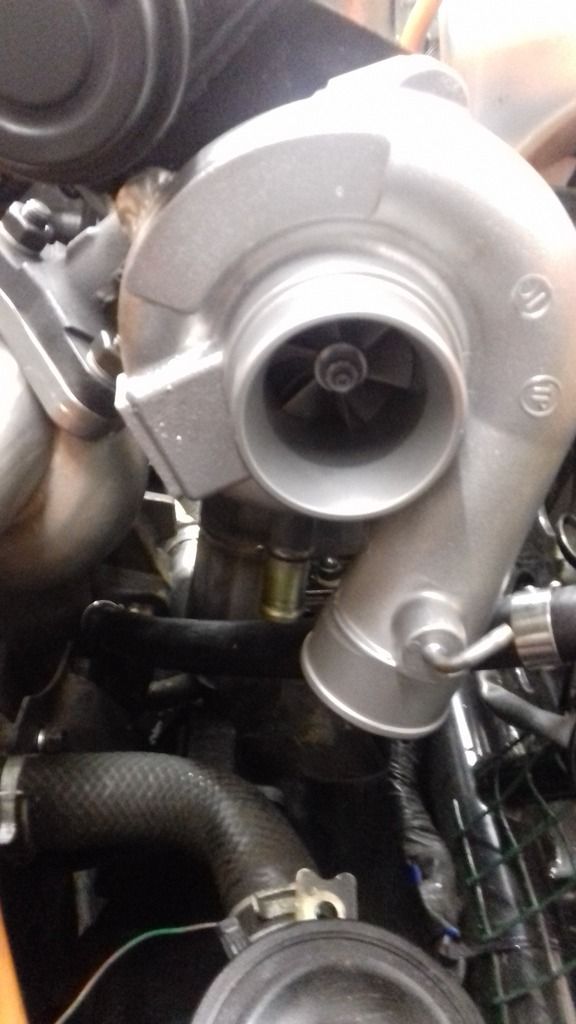

So today i replaced the dipstick with the new one for the oil return as this saves having to drill the sump. Very simple job  I also fitted and torqued the new manifold to 42 n/m and used some of this stuff. I also fitted a new gasket.  I finished my 3 intercooler mounting brackets  I bolted on the turbo and the kit comes with lock washers. The turbo was already clocked by G19 but the oil return pipe is sitting at about the 7 oclock position rather than were i would of liked it at 6 oclock/ vertical. Does this matter and is it worth removing the turbo and trying to clock until vertical? You can see from below pic the oil drain tube is sitting at a slight angle or am i being too fussy??   This turned up todayAEM X Series wideband  |

|

|

|

Post by gwnwar on Dec 24, 2016 5:17:24 GMT

The oil return is ok as is.. Do you have a good "O" ring on the dip stick tube..

In the past I have had the nuts loosen on the turbo mount. I went to nuts drilled that I could safety wire in place..

|

|

|

|

Post by gwnwar on Dec 24, 2016 5:22:34 GMT

The oil return is ok as is.. Do you have a good "O" ring on the dip stick tube and it secured good to the engine.

I would use a larger return then the dip stick tube with a dip stick in it. Pan is easy to tap if tube doesn't work out..

In the past I have had the nuts loosen on the turbo mount. I went to nuts drilled that I could safety wire in place..

|

|

|

|

Post by scooby1929 on Dec 25, 2016 15:39:15 GMT

The oil return is ok as is.. Do you have a good "O" ring on the dip stick tube and it secured good to the engine. I would use a larger return then the dip stick tube with a dip stick in it. Pan is easy to tap if tube doesn't work out.. In the past I have had the nuts loosen on the turbo mount. I went to nuts drilled that I could safety wire in place.. Hi George a very Merry Xmas to you For the nuts on the turbo the kit comes with 2 serated lock washers which prevent the nut from coming loose but a good call on wire locking. I am going to get some drilled nuts and wirelock as an additional method of preventing this from loosening. George have you any advice on where the 2 vac hose on the turbo route to?? One is on wastegate and the other on the turbo outlet? |

|

|

|

Post by gwnwar on Dec 26, 2016 17:33:31 GMT

If looking for a vac source on the intake/on throttle body

|

|

|

|

Post by scooby1929 on Dec 28, 2016 19:07:43 GMT

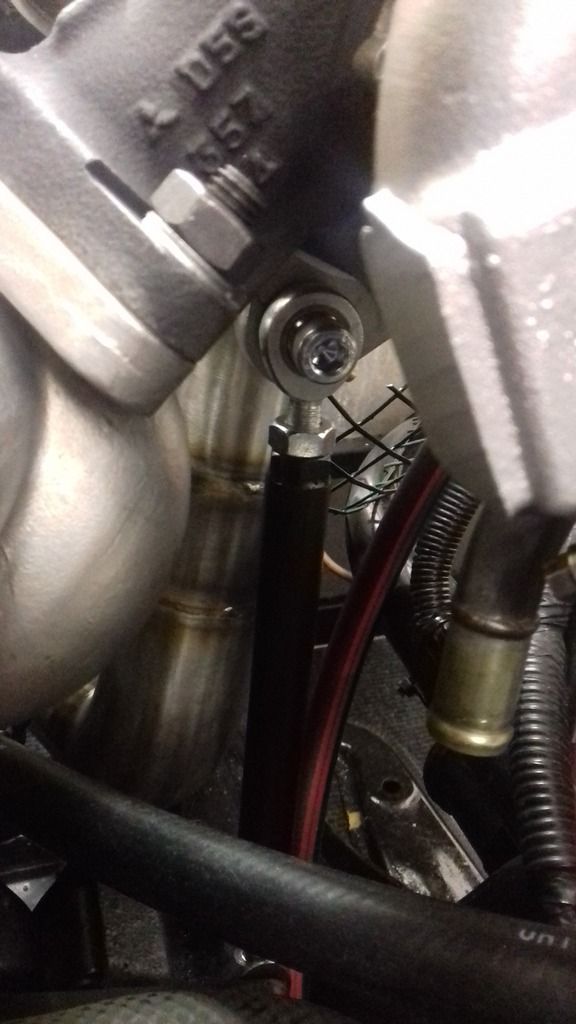

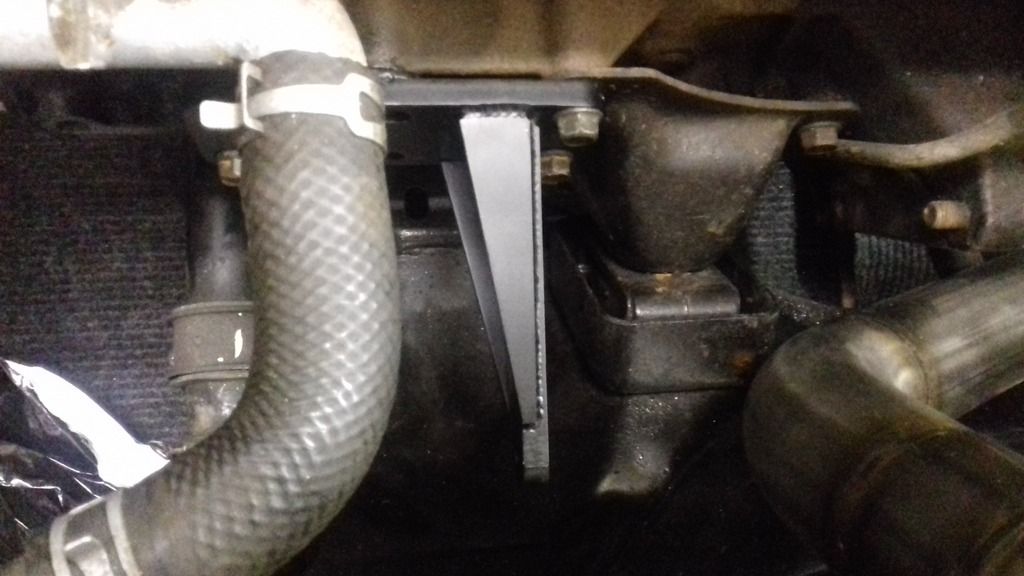

So today i adjusted the brace bar so that its taking the weight of the exhaust etc  Then i plumbed in the turbo. The beauty about having a pre 96 1.8 mx5 is that the oil feed is on the side of the block.  I have decided not to fit the oil feed at the top just yet as i am going to prefill the turbo with new engine oil. I was going to use a syringe for this anyone know how much to put in? I will be p clipping this on to the side of the rocker cover as you do not want this pipe working its way loose  The water pipes connect as shown i need to trim one of the pipes before i connect it  |

|

|

|

Post by gwnwar on Dec 28, 2016 21:31:58 GMT

With the brace bar.. Top is going to the turbo exhaust manifold looks like to a small ear on it.. Were is the lower end attached

too.. The engine block, motor mount at frame..Can't really see.. if to frame not engine I would be worried for torque roll might break the ear off after awhile.. If mounted to engine it would be all one mass moving together.. Nice clean install..

|

|

|

|

Post by scooby1929 on Dec 28, 2016 22:05:14 GMT

With the brace bar.. Top is going to the turbo exhaust manifold looks like to a small ear on it.. Were is the lower end attached too.. The engine block, motor mount at frame..Can't really see.. if to frame not engine I would be worried for torque roll might break the ear off after awhile.. If mounted to engine it would be all one mass moving together.. Nice clean install.. Yes George there is an additional lug on the exhaust and the other end attaches to a bracket that i mounted onto the engine using 2 off the engine mount holes and 2 other additional existing holes.   |

|

|

|

Post by scooby1929 on Dec 29, 2016 11:45:41 GMT

Todays quick wee job was too install my ME221. I opened up the box from G19 and the serial connector for laptop and vac hose were all connected and a basemap uploaded. I had made up some small brackets to hold previous ECU in place and these lined up exactly so happy days  |

|

|

|

Post by gwnwar on Dec 29, 2016 23:13:50 GMT

Don't forget to install the hard water tube under the exhaust manifold from water pump to rear of engine.

Didn't see it in any pics. or you are just not there yet.. Don't forget the "O" ring on end of tube..

|

|

|

|

Post by scooby1929 on Dec 30, 2016 0:19:44 GMT

So tonights job was to wire in the AEM X Series Wideband. Thought it was best to wire it in on the loom close to the new ECU and mate Philip came round to give me a hand as this is first time i have been slighly cautious especially cutting wires to ECU. So connected the white wire analog + pictured below to the existing narrowband connection which is a red / black + 0-5 v. I got this from a wiring diagram but i also did a continuity check between wiring to ECU and plug that i disconnected old narrowband from. The brown analogue - i connected to a black ground on loom to ECU.  I then was unsure which connector in ECU gave a 12 v switched supply so i wired the red wire to a switched live on the ignition under steering coluumn. The black wire i just wired to the same earth as above. On this particular wideband there is 7 wires but the other 3 appear to be used for datalogging, going to a serial output etc so just taped them up. Turned the ignition on and have power on the Wideband so happy days hopefully this is correct.  Dont like the way under my user name it says the word EXPERT i am most certainly not that ha ha |

|

|

|

Post by welshy1 on Dec 30, 2016 21:02:05 GMT

If you are using a boost controller then the 2 outlets on the turbo go into the boost controller loops around that's how mine is set up.

Just had delivery of my new cast manifold from g19 he give me a deal I couldn't refuse cant wait to get it fitted on to the new engine.

|

|