|

|

Post by Fin on Mar 14, 2017 9:29:58 GMT

Looking good. You've probably picked up on this thought from your forum reading anyway, but just in case - try to ensure you don't put a rivet in where your seat bolts will be coming through. Hope you're armed with a lazy-tong or better for the riveting job ahead! Thanks. I'd spotted that, but it always helps to be reminded. You reckon a lazy tong is a must have then? Unless you have arms like Popeye :-)) |

|

|

|

Post by Fin on Mar 16, 2017 9:52:21 GMT

Exocet does not use those runners, you need the ones without the seat belt mounts attached. IVA is an issue with the type you have as belt anchor points will rely on the 8mm bolts holding the seats down. You need to use 12mm bolts for the seat belts in the floor mounting plates. Still puzzled. Having flattened & welded the angled runner mount, can I now affix the runners to the 20 x 20mm cross-chassis tubes with M8 (or M10) bolts right through the tube & flooring? Had originally thought to use a threaded crush-tube but 20mm cylinder into 20mm square doesn't go, unless I can find smaller diameter crush-tubes. Seatbelt harnesses will be fitted with M12s, or possibly with the shoulder wrapped over a harness bar. |

|

|

|

Post by Stiggy on Mar 16, 2017 10:15:04 GMT

No crush tubes or welding required.

8 mm bolts for seats and 12 mm for belts, IVA OK provided belts are not mounted on seat frame.

|

|

|

|

Post by Fin on Mar 16, 2017 10:23:03 GMT

No crush tubes or welding required. 8 mm bolts for seats and 12 mm for belts, IVA OK provided belts are not mounted on seat frame. So 4 x M8s right through cross member & flooring with bolt-head on floor exterior? |

|

|

|

Post by miket on Mar 17, 2017 11:49:52 GMT

Yeah but consider a thick M8 SS washer or plate as a load spreader below the floor exterior. Which way up to put the bolts has different opinions- bolt head underneath to minimise potential for speed bump impact or nut underneath so that in the unlikely event of a nut loosening at least the bolt stays in place. I think it's been done both ways and with/without load spreaders for IVA, but I've not checked specifically.

|

|

|

|

Post by Fin on Mar 17, 2017 13:43:13 GMT

Yeah but consider a thick M8 SS washer or plate as a load spreader below the floor exterior. Which way up to put the bolts has different opinions- bolt head underneath to minimise potential for speed bump impact or nut underneath so that in the unlikely event of a nut loosening at least the bolt stays in place. I think it's been done both ways and with/without load spreaders for IVA, but I've not checked specifically. Thanks. Will do that. Can see reason in both bolt up/bolt down, but given there are three others retaining the seat, and hundreds of speed humps, I think I'll go with bolt up, and your washer. |

|

|

|

Post by Fin on Mar 17, 2017 18:35:40 GMT

Well, another surprise - a drip tray. Thanks to Gumtree, I managed to source some off-cut galvanised metal sheets for a fiver from a place in Burton, so tomorrow might involve fitting the driver footwell and passenger firewall, and manipulating a sheet of this to fit under the tank's location. Seems to be needed only over the exhaust, but might shield the whole section and plumb in a drain pipe - just in case.  He also had an abandoned Mk1 MX5 in case anyone is looking for a pretty rough donor, or box of spares!   |

|

|

|

Post by Fin on Mar 18, 2017 17:39:12 GMT

Quiet day measuring and marking the flooring panels for rivnuts, thanks to mawdo81 's loan of an all singing-all dancing rivnut gun. It must have carried OCD traces, as I realised measuring the panels individually and spacing the rivnuts evenly would mean the two panels didn't quite line up studwise. Although it's not going to be seen, I wanted the rivnuts in line and so traced the first panel spacing onto the second. Just got to mark the cross-struts when the seats are drilled, and I can temporarily screw in the floors.  |

|

|

|

Post by Fin on Mar 20, 2017 19:57:32 GMT

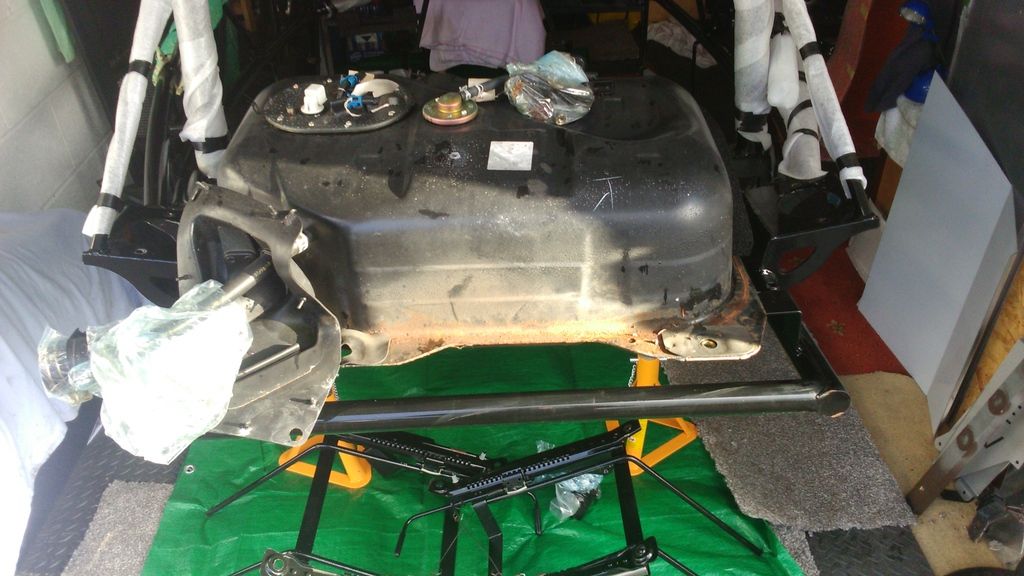

Stories of fitting the bulkhead/firewall and tunnel suggest that the process can be fraught with problems, so decided to confront the inevitable. Started with what I thought would be the easiest piece, the driver's footwell. Much to my wife's amusement, it became easier when I tried to fit it the right way round, but managed to convince her this was a legitimate fabricating tactic called "reverse engineering". A bit of chopping, bending, filing and general fettling gave a pleasing result, plus an understanding that "it'll do" never will, even when out of sight.  Rivnuts should be here tomorrow, but may just pop-rivet it anyway, but first it needs carbon-wrapping and maybe painting engine-side. Flipped the chassis the right way up and put on some more protective wrap - drilling and dropping stuff is on the increase - and then thought I'd offer up the fuel tank to see what problems awaited. Am I right in thinking this already has a drip-tray affixed? An if so, cleaned up and tidied, will it suffice for IVA or am I better fabricating something much more basic from new material?   Tried it both filler left & filler right and given some of the recent horror stories about the incorrect mounting brackets, it was closer than expected. Just seemed that some of the holes were in the wrong position.     |

|

|

|

Post by scottmev on Mar 21, 2017 15:25:01 GMT

In regards to fuel tank.

Best fit I got was filler behind driver. Rearmost right hole didnt match up so am just making a small extra piece to bolt to existing mount then to tank to bridge the gap. Will upload a photo later.

|

|

|

|

Post by Fin on Mar 21, 2017 16:14:26 GMT

In regards to fuel tank. Best fit I got was filler behind driver. Rearmost right hole didnt match up so am just making a small extra piece to bolt to existing mount then to tank to bridge the gap. Will upload a photo later. Mine probably looked better that way too, but that puts the fitted drip tray/heat shield away from the silencer! |

|

|

|

Post by scottmev on Mar 22, 2017 12:42:02 GMT

I am going to make my own out of some ally. I believe the fitted one is not suitable for IVA.

|

|

|

|

Post by freshp5 on Mar 22, 2017 14:58:20 GMT

We not got one on the mevster that pass Iva is it a new rule  ?? |

|

|

|

Post by Fin on Mar 22, 2017 15:01:16 GMT

We not got one on the mevster that pass Iva is it a new rule  ?? Seems to have been around for a while Dave, but popping up in many Exocet builds. |

|

|

|

Post by Fin on Mar 22, 2017 20:24:15 GMT

Day of experimentation with mawdo81's rivnut gun. Started badly when the incomprehensible "manual", actually a series of pictures, made Ikea's instructions look like a piece of cake. Fortunately, YouTube to the rescue, and after four practice attempts I felt confident enough to try for real.  Decided to fit the transmission tunnel first, and set a rivnut on either side at the gear lever end which allowed me to mark and drill the chassis at 10cm centres along the straight driver's side. Easy enough to whip it off to deburr the drill holes, and dab some metal paint into the chassis holes.  On the dogleg passenger side, I re-fixed the gear lever end, and then drilled the engine end. The notch in the tunnel is fractionally past the bend in the chassis, but exerting enough weight & outward pressure on the tunnel to splay it into place for marking and drilling seems to be a two man job, so will need to wait till the weekend. The length of the tunnel will need a little trimming, but need to finish the template for the passenger firewall to allow enough to fold back inside the tunnel to give a neat rivetted finish.  Only downer on the day was the bloke at the garage billing me £30 for 2 x 2" of welding on the seat runners. "Not much" he said to yesterday's enquiry about price! |

|