|

|

Post by stecz on May 6, 2016 12:51:22 GMT

I'm at the point in my build where I'm installing the wiring harness (Left Hand drive), but I'm trying to figure out where to run the wiring between through the firewall. On the passenger side (right side), I can use a hole saw and cut a hole through the firewall and use the original rubber grommet. But on the driver's side (left side), there really isn't space for that grommet. What solution have other folks used? Just run the harness over the cross bar with some sort of mount (p-clip or zip-tie mount)? Looking for ideas here.

thanks

|

|

|

|

Post by zeitgeist on May 6, 2016 13:30:30 GMT

I ran mine over the bars at all the points so far. I plan to reduce unnecessary wiring this year in the off season and then route them through the firewall where I can when the bulk is reduced and the harness is unbound then rewrap and add corrugated wire sleeve.

|

|

|

|

Post by stecz on May 6, 2016 13:35:49 GMT

I was considering that route as well. I want to install the wiring, without cutting anything, get the car running, and then start removing the unnecessary wiring. That way I have a fighting chance of resolving any problems I might create by removing wiring.

This build has taken much longer than I intended, so I really want to get the car running, drivable and registered, so I can have fun with it and then go back when I want to and make things better.

|

|

|

|

Post by dietcoke on May 6, 2016 13:38:37 GMT

I used a 1" holesaw and cut a hole on the driver's side and used a grommet.

|

|

|

|

Post by jwagner on May 6, 2016 14:12:22 GMT

I also cut a hole through the firewall and used a grommet. There's a bunch of stuff you can cut out right away. You don't need the wiring for the headlight motors or the air conditioning or power windows or ... Just make sure you trace the wire back before you cut, because there are a lot of splices in the loom and it's easy to cut something out you didn't mean to. It might make sense to lay the loom out where you want it and get the car running before you cut a lot of stuff, but I would't do any final routing until you cut out the unused stuff.

The wiring stuff is a pain and takes time, but stay with it and it sorts itself out eventually. We ran our first autocross event with a rats nest of wires duct taped down into the wiring tray.

|

|

|

|

Post by gwnwar on May 6, 2016 17:28:10 GMT

stecz.. If you would add a signature line to your profile/threads with year and engine and location it will help

if you need help trouble shooting a problem..

|

|

|

|

Post by stecz on May 6, 2016 18:11:42 GMT

So basically, cut a much smaller hole than factory for the driver's side and tread it through... sounds good.

|

|

|

|

Post by stecz on May 6, 2016 18:15:22 GMT

On a related note... attaching wiring.... I was going to use zip tie mounts screwed to the frame tubesand use that to run the wiring against the various frame tubes. I was thinking p-clips also, but I would need a bunch of sizes.

|

|

|

|

Post by jwagner on May 6, 2016 19:29:57 GMT

I directly zip tied plastic split wire loom (several sizes) to the frame where possible and used wire tie mounts for flat surfaces. If you use the self-adhesive mounts get industrial grade and skip the cheap chinese stuff - it will fall off in time. I also wrapped the entire wire loom in black cloth electrical tape to eliminate the possibility that it would rattle around in the loom or chafe against anything and wear through the insulation over time. Use caution with plastic electrical tape since it tends to shrink and leave gooey adhesive, especially when it gets warm. (I wonder what sort of magic plastic tape Mazda uses when it builds cars - it doesn't do that as much.)

|

|

|

|

Post by jgilbert on May 6, 2016 21:38:39 GMT

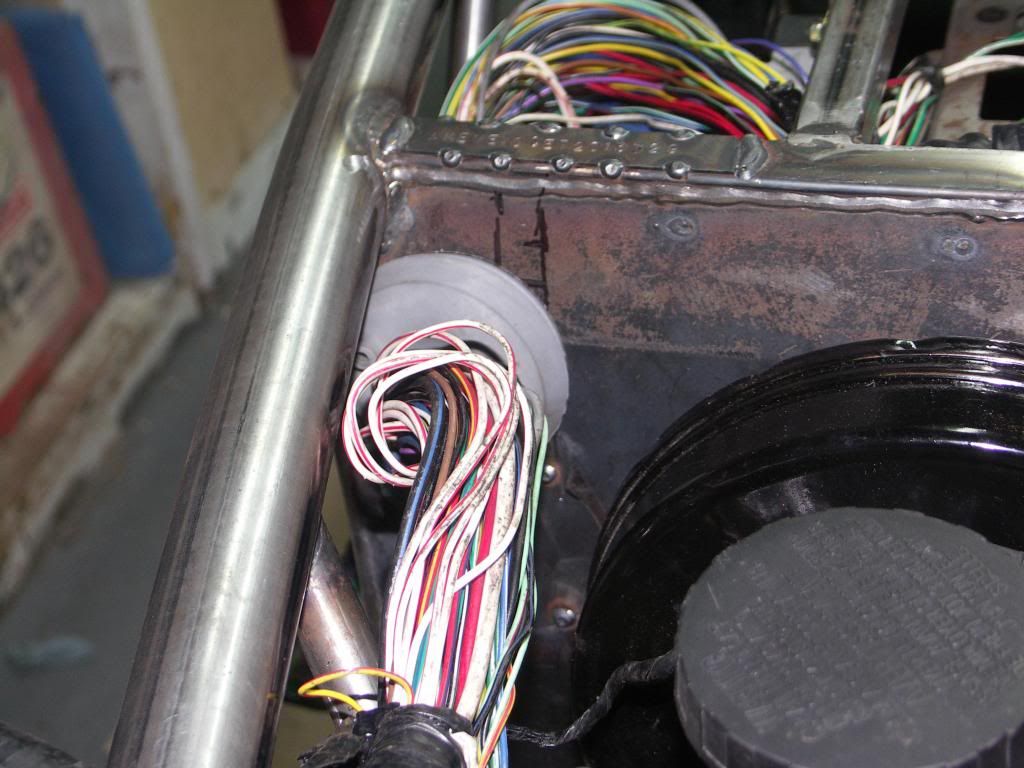

I'm at the point in my build where I'm installing the wiring harness (Left Hand drive), but I'm trying to figure out where to run the wiring between through the firewall. On the passenger side (right side), I can use a hole saw and cut a hole through the firewall and use the original rubber grommet. But on the driver's side (left side), there really isn't space for that grommet. What solution have other folks used? Just run the harness over the cross bar with some sort of mount (p-clip or zip-tie mount)? Looking for ideas here. thanks Stecz, Page 8 of my build thread has the answers to where on the drivers side you can cut an hole for the loom grommet. Photos below will give you an example of whats possible.   |

|