|

|

Post by carlyd on Jan 3, 2019 16:03:02 GMT

Regarding the brake pipes, most people use a short piece of flexible pipe (such as small fuel pipe) with a tie wrap passed through and around the wishbone/ brake pipe to hold the brake pipes in place. This allows a little bit of movement and flex.

|

|

|

|

Post by casesensitive on Jan 3, 2019 16:31:42 GMT

Regarding the brake pipes, most people use a short piece of flexible pipe (such as small fuel pipe) with a tie wrap passed through and around the wishbone/ brake pipe to hold the brake pipes in place. This allows a little bit of movement and flex. Ta! I saw a thing I liked on someone else's car which was an asymmetrical p-clip, one side with interior diameter of the brake pipe, one with ID of the wishbone, but your way is much cheaper and can be done with stuff I already have, so that then. This project has gotten to the silly point; at the beginning I tracked the cost of every bolt and tool, it was a small 5 figure sum when I stopped counting, years ago, and solution of late has been throw money at an issue until it goes away. Leading to nice stuff like the Willians harness but daft purchases that make no sense either. Heated seat pads anyone? How about a full set of beautiful but IVA-failing front suspension bolts out of A2-70 stainless? |

|

|

|

Post by casesensitive on Jan 3, 2019 18:24:56 GMT

Brought one of the bones to Halfords with me to find a better colour match, which, aside from the silver flake, isn't far off, close enough for the underside of my wishbones   |

|

|

|

Post by kiwicanfly on Jan 3, 2019 18:28:15 GMT

Why will the stainless bolts fail IVA and what are you using instead?

|

|

|

|

Post by casesensitive on Jan 4, 2019 14:41:52 GMT

Why will the stainless bolts fail IVA and what are you using instead? Suspension bolts all need to be 8.8 grade or stronger, and the shiny A2-70 ones don't have the equivalent tensile strength, whereas A4-80 are close enough to be accepted. |

|

|

|

Post by kiwicanfly on Jan 4, 2019 18:41:04 GMT

Thought that might be the case, we allow A2-70 even though lower than g8.8. I couldn't get A4-80.

Strangely we also have an upper limit of g10.9 on parts such as suspension, can't use g12.9.

The one place which worried me with stainless bolts was fitting the stub axles, I used Bumax which are stainless but rated pretty close to g12.9.

|

|

|

|

Post by carlyd on Jan 6, 2019 11:21:31 GMT

Brought one of the bones to Halfords with me to find a better colour match, which, aside from the silver flake, isn't far off, close enough for the underside of my wishbones  I know Deano had his chassis colour changed to green and was planning on painting the suspension arms in satin black making it look more F1 or race car like, so if you are stuck for a colour match in future that may be a good option. |

|

|

|

Post by casesensitive on Jan 7, 2019 10:47:21 GMT

Brought one of the bones to Halfords with me to find a better colour match, which, aside from the silver flake, isn't far off, close enough for the underside of my wishbones  I know Deano had his chassis colour changed to green and was planning on painting the suspension arms in satin black making it look more F1 or race car like, so if you are stuck for a colour match in future that may be a good option. I've all but accepted that when the car is finished and registered, I'll strip it down and re-powdercoat it the colour I actually wanted and ordered in the first place, Ford Imperial/Performance Blue. When I saw the colour free got his, I knew I'd never be happy with mine ;/ My car looks the right colour in poor light, but the colour in the sunlight is too light a shade. I picked from a swatch at the powdercoaters, but we were indoors in a dark industrial unit. Plus, it's pretty badly scarred up from scratches and changes, and anywhere the powder has been removed and repainted, the height is noticeably different, 3 primer coats, at least 3 paint coats and 2 clear is still nowhere near as thick as the powder. Not for now, but manana. |

|

|

|

Post by casesensitive on Jan 22, 2019 18:04:23 GMT

Regarding the brake pipes, most people use a short piece of flexible pipe (such as small fuel pipe) with a tie wrap passed through and around the wishbone/ brake pipe to hold the brake pipes in place. This allows a little bit of movement and flex. Yeah, that's better alright.  |

|

|

|

Post by casesensitive on Jan 22, 2019 18:08:30 GMT

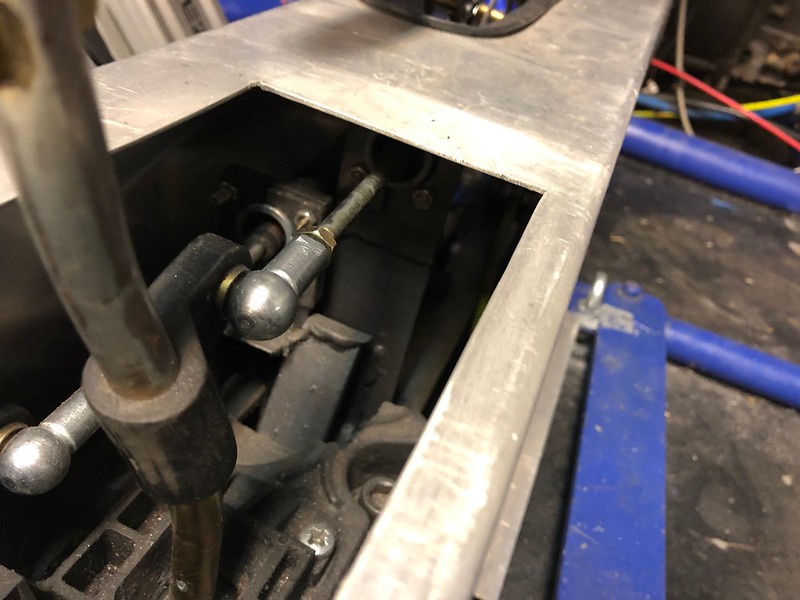

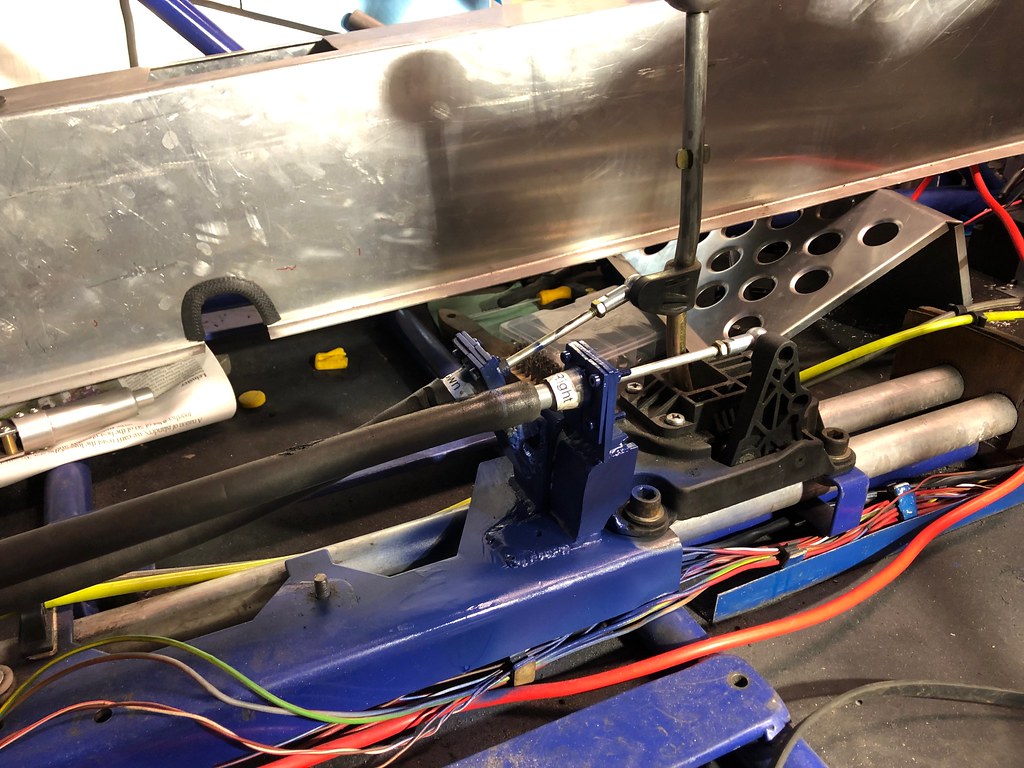

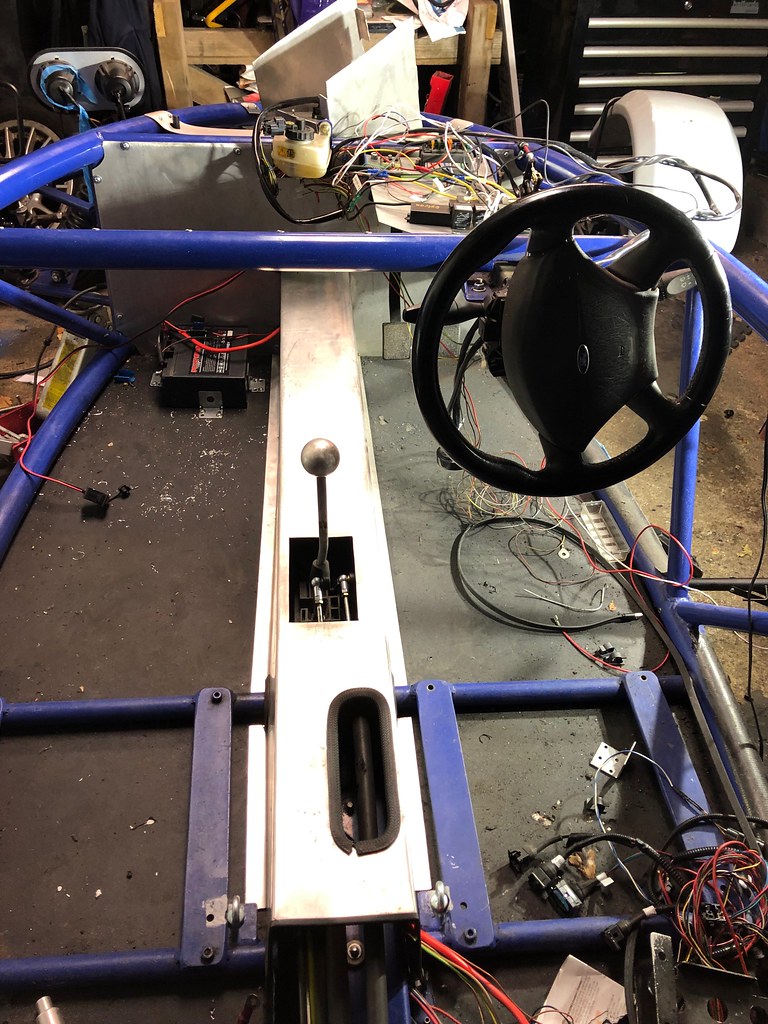

The Inter-connectedness of all things is funny in a Douglas Adams book, a bit of a pain in a Rocket. I refit my tunnel to line up where I'd mount my battery, only to discover it no longer fits!   Turned out to be my gear selector mount, so it go cut, again.  It's in a right pita place to weld, currently hastily tacked, and will probably get some rear support when I have a decent full day at it  At least I can paint it properly this time around. |

|

|

|

Post by casesensitive on Jan 22, 2019 18:13:20 GMT

Using some Aldi jump leads, ripping off the plastic parts, squashing and drilling to M5, I had my positive line, nice short negative to the body  Ctek charge panel  Mounted on 3 sides it shouldn't go anywhere, and still enough height on my terminals to jump it if I need to.  Need to make a removable side panel for the passenger footrest  |

|

|

|

Post by carlyd on Jan 23, 2019 10:51:39 GMT

Regarding the brake pipes, most people use a short piece of flexible pipe (such as small fuel pipe) with a tie wrap passed through and around the wishbone/ brake pipe to hold the brake pipes in place. This allows a little bit of movement and flex. Yeah, that's better alright.  No, like this (below). I have changed the colours to make it easy to see, the fuel pipe is yellow and is stood on it's end, the tie wrap is green and is passed through the fuel pipe and over the brake pipe and chassis. This allows flexibility.  |

|

|

|

Post by casesensitive on Jan 29, 2019 8:25:12 GMT

Small jobs this past weekend, caliper is goosed, more on that thread. Bit of etch primer, paint and clearcoat on the revised gear selector 'mount'  Then some convoluted tubing over the wiring, some of which dips under the cooling pipe mount in places, to allow the tunnel to fit. Feels like that could be better. At least it closes now.   Project A4-80 continues, all SS up front now. Finding the two M10 x1.5mm thread nuts in the garage was a fun time, easily an hour spent on that. FML.  |

|

|

|

Post by casesensitive on Feb 11, 2019 9:37:25 GMT

Mission for the day was to get the wheels back on and coolant system filled, ready to spark up next week. Messy time getting the suspension all fitted up, few bolts had to be shortened, and a lot of pry-bar leveraging to get some of them in. Final fix of the new engine mount  Refitted and bled the clutch line  Tightened up and filled the cooling system with water, put down newspapers to check for drips. Found one from the coolant expansion tank, but looks good after that jubilee clip was nipped up.   Then I aligned the front wheels a bit, with the tools to hand, one-handed clamps and long bits of steel. Close enough till I get it done properly.    |

|

|

|

Post by casesensitive on Feb 24, 2019 11:09:20 GMT

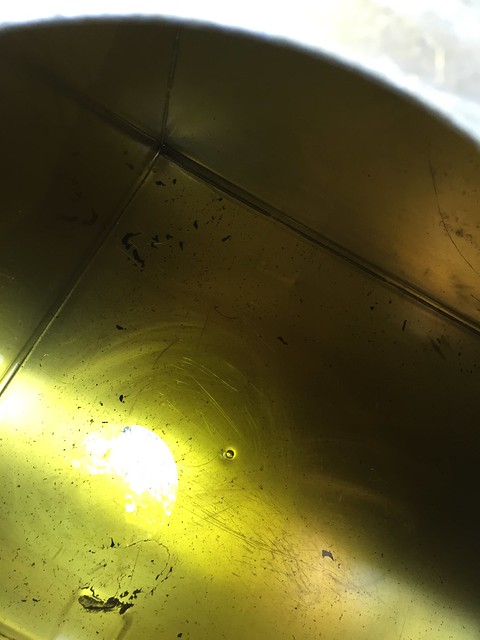

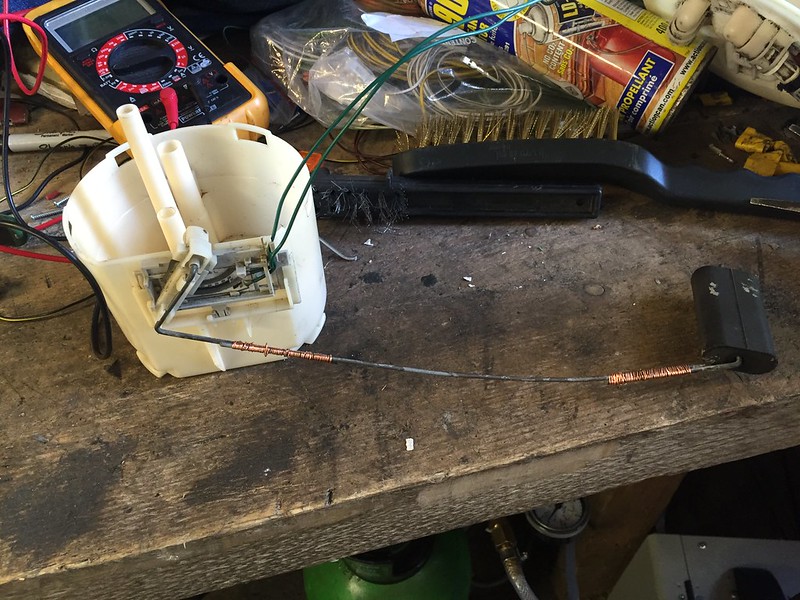

In 2013 when I was starting out, I used some fuel proof sealant and tape to extend the fuel gauge arm with some coat hanger, and to hold the base of the sender to the tank. 2.5 years on, predictably, the sealant is rubble,  and the arm is freer than it should be. The plan was to wrap copper wire around it so I could spot weld it, but the copper was tight enough that the weld isn't needed.   Last week's attempt to get her to fire up were cut short by a dead fuel pump, been sat up for 9-12 months and didn't want to know. It looked like this when it came out.  Another cheap pump of a similar type was procured and it seems that the good people at the Chinese Copying shop missed a trick, or knocked off early maybe. See if you can spot what part they didn't bother getting right.  Fortunately, I still have the original broken Focus fuel pump, with the correctly-angled filter. It was dirty, so I used my new fuel/oil pump to push acetone through it backwards. This, or the petrol, melted the pump switch, interestingly. The extended arm I made up 2 years ago hasn't worked out, the copper wire I wrapped around the coat hanger to keep it together seems to have caused some sort of green scum in the tank. I tack welded the bits together instead, making sure not to add too much weight, tested the floatation in the sink.   Pumped the fuel out, filtered it, and cleaned out the tank properly, stripping the sealant at the entrance.   Put back in 5l of fuel, tested the pump and left it unsealed for now, till I figure out some way I'm happier with. I'd be happier with some sort of mechanical fitting. Edit: Maybe rivnuts with a rubber gasket? |

|