|

|

Post by ridgeback on Jun 29, 2015 16:40:47 GMT

Demon tweaks do a pair of purpose made convertors to do what your trying to do with your redtop.

Ebay item no.311354088770 cost £17.00 free postage.

|

|

|

|

Post by casesensitive on Jun 29, 2015 19:24:17 GMT

Demon tweaks do a pair of purpose made convertors to do what your trying to do with your redtop. Ebay item no.311354088770 cost £17.00 free postage. Thanks for the find. Yeah, I spotted that CBS had something similar, and I balked at the excessive cost, hence the bodge. If my shiny new battery without terminal hack works more effectively Ill have to suck it up (or buy copper M6 threaded bar / screws?). |

|

|

|

Post by casesensitive on Jun 29, 2015 19:29:41 GMT

M6 brass bolts, chop off the ends? Is the connection between the lead and the brass/steel going to be a concern? I don't remember lead being termed a good conductor back when I learned such things. Why make the battery terminals out of it? The internet sez: hmm.

|

|

|

|

Post by kiwicanfly on Jun 29, 2015 19:53:32 GMT

Lead is a better conducted than steel, about twice as good and about half of brass which is only about as third as good as copper.

The reason the terminal was made of lead will be because it was part of the plate inside the battery thereby eliminating a joint.

I have not checked but I bet your new battery is not a lead/acid unit whereas your sacrificed battery was?

Apart from the conductivity of the materials used there is also the cross section size to consider, a poor conductor can be compensated for by increasing the cross section, so if the conductivity is half then double the area and you should be right in theory.

This assumes no loss due to a poor interface, ie the two faces join perfectly with no irregularities, gaps or corrosion.

In your pics the terminal had a gap between it and the battery so all the current had to go through the steel screw, at M6 the root of the thread was 5mm, way less than the diameter of the terminal. So you now have a poor conductor with small cross section hence my comment it had effectively become a resistor.

|

|

|

|

Post by kiwicanfly on Jun 29, 2015 21:57:20 GMT

Returning to the issue of the car not starting.

I used a Omex ECU and Omex loom so had a few advantages from that point of view but I tackled it in small bits.

The first thing I did was to see if the starter motor turned over then worked from there.

I did all of this with a jumper pack as I did not have a battery at the time and even the starter was sitting on a bench behind the car.

Essentially what I am saying is that hoping for the car to start first time is what we all hope for but working through each part of the circuit in order is an easier approach.

|

|

|

|

Post by pocketrocket on Jun 30, 2015 1:19:20 GMT

I'm not sure I understand what the battery terminal issue is?  would you not be better off changing the lead terminals to suit, rather than having all these adapters & stuff? |

|

|

|

Post by casesensitive on Aug 3, 2015 15:37:07 GMT

Ok, spent a little time on this this weekend. 'grey metal box' turned out to be the Inlet Manifold Runner Control box as suggested by dgibson. Located it and plugged it in, but that wasn't the only thing, still no life out of it.  Mostly it was a lack of ground lines; so I gathered up anything with a black wire or a circular spade connector and clumsily connected them together with a butchered 13amp extension cable, M6 screws and nuts.   And it lived! Got lots of warning lights, which normally would worry me, but I was delighted.  |

|

|

|

Post by casesensitive on Aug 3, 2015 15:51:59 GMT

Tidy up the loomWith signs of life, I got to work correcting bad connections and removing what I didn't need. Fuel sender float position was not affecting the fuel gauge, and I discovered one of the 4 wires was torn right at the connector. Connector was well crimped and I couldn't get the mushed wire out, I didn't have any compatible spares and Halfords and Macquillans weren't much help either, so I committed my first wiring crime (of many!) and soldered the line to the old, very closed, spade connector.  With the float a little past half way, gauge was about half, nice. Low value on my multimeter looked around 100ohms, and about 2/3 was 212. Couldn't get multimeter poles onto contacts with the float at full, but I'll measure them again before I seal it. I'll be using a Koso dash later so this will be important down the line.  I spent the next 2 hours peeling the loom, ended up with dozens of metres of black tape everywhere. Much easier to see where everything goes this way, but boy is it sticky. Rips latex gloves, and thicker gloves lack the finese to unravel it.  Removed all the interior wiring loom, lights etc and stuck it in an Ikea bag, loom now half the weight.  The central locking module is still in the picture, unconnected, because half the connectors on this side of the loom are still attached, have to peel a fair bit off before I get to the bottom of all of that.  What's the point, you might well ask? I have an Omex 710 ECU to go in later, with a race loom (for an Opel, will need some modification), so most of this will be chucked out. I just wanted to make sure the car starts (fuel lines and better ground wiring before that happens!) on the stock gubbins before I introduce elements I don't know work with these pieces. The ST170 has a kooky fuelling system (returnless, with Driver Fuel Pump Module) and a non conventional air intake (my MAF is on a custom cold air feed pipe, and the IMRC changes the intake path at high revs). Not sure how my Omex will handle the IMRC. If it doesn't, I might jump straight to the GXSR ITBs.. It's good to see where everything goes too, maybe relabel it with accurate names.

|

|

|

|

Post by casesensitive on Aug 14, 2015 14:27:50 GMT

So I found out why I couldn't get the lump to crank on the stock gubbins.  I asked for help on here, and after reading a few other people's guides, I went to youtube to educate myself. After watching these, I've done a series of voltage and continuity tests and have come to a conclusion.. From the spec sheet, my Varley Red Top should be capable of 310A. While my starter wiring could be questionable, it's unlikely, because I never disconnected any of that stuff when I took off the engine loom, it's been hanging out of the engine since it came out of the Focus. There's a pd of nearly 13V between the -ive pole of the battery and the starter solenoid terminal (with in-line trickle charger). But, it falls off a cliff when I turn to Pos III. Like, two brief attempts and battery voltage falls to 11.4v. To confirm, I took it to a battery place here that does free battery voltage and CA (cranking amps) tests. I didn't expect him to find it anything else but faulty, part because in my heart I suspected it was, and because he'd go broke testing batteries and finding them good. Test equipment looked legit. Voltage 12.5V, nice, but a paltry 16 CAs, conclusively knackered.  So kids, don't buy second hand batteries on ebay, and then leave them on the shelf for months. <facepalm> The guy would sell me an Odyssey Extreme PC680 for €130 or a generic alternative (Leoch LPX600) with identical specsheet for €80. Both 7Kg, both with similar cranking capacity. Which is about what I threw away on this junk Red Top  Anyone used these Leoch batteries before?  |

|

|

|

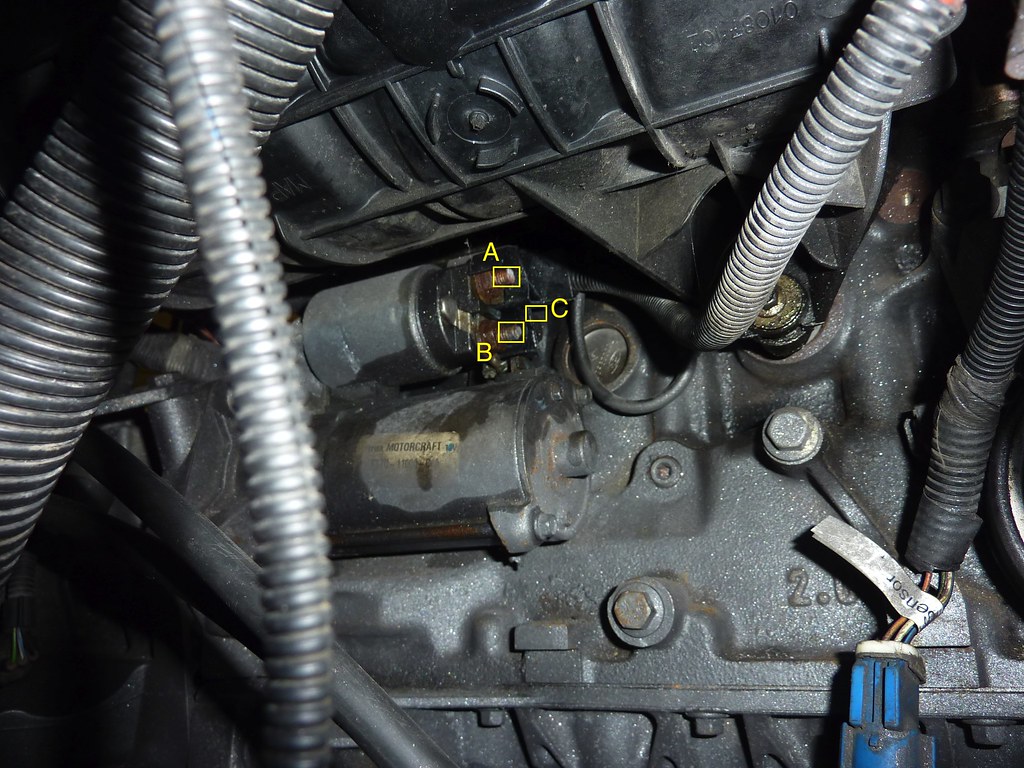

Post by casesensitive on Aug 14, 2015 14:35:58 GMT

Plan for the short term is to use jump cables from the Alfa (Serena has a big battery) to see if I can tease it into life, and if I can, conclude that my battery was dead money. Ug, I just looked up how much I paid for that p.o.s. battery. From Momentum Motorsport, if anyone is curious. If the starter or wiring is dodgy, the whole inlet manifold has to come off to get at it, which is a big mess. I've tried shallow and deep sockets, with and without extension bars, I just can't get at the nuts with the mani on. please please please turn over. :-) |

|

|

|

Post by casesensitive on Aug 24, 2015 8:27:43 GMT

Quick RackStarting with things that went well this weekend. The quickrack conversion looks like a nightmare, honestly, so I took the easy and cheaper route to less wheel turning. Rather than buy a new set of internals and swap them over, I bought a second hand quick rack from a Sierra. Probably a 2WD Cosworth, though the auction was labelled 'Burton'. 2.4 turns lock to lock, which is actually a touch quicker than the Rally Design one. Search 'Sierra quick rack' on Ebay, set up an alert and wait for the right one. In short, it worked, and after successfully trial fitting it, I found it to be about as good nick as my RTR-supplied new part, so I cleaned the guck off it with engine cleaner and water, touch of hammerite, and stuck it in as-is. Job's a good 'un.  The Da popped by, so I gave him a shot at driving my new rack  A slap of paint  and in she's goes  Proof of the pudding www.flickr.com/photos/43278150@N00/20831156201/in/dateposted-public/

|

|

|

|

Post by casesensitive on Aug 24, 2015 10:34:17 GMT

Clutch linethe long saga of my clutch line may finally be at an end. Picked up the last two pieces, a 3/8ths-24 tpi banjo, and a 3/8ths-24 tpi banjo bolt (not chromed, or matching my other two outlets, may replace this down the line if I can justify it) to run from my MC outlets to the lime green 3m clutch line Stewart supplied me with. This connects to my homemade focus end (M12).   I first bled the line straight back into the brake fluid bottle until I was absolutely certain it was airlock free, then  Then I connected up my 'one man bleed kit' (the cheek, it's a bottle with a valve on some 8mm tubing! ) to the bleed nipple on the gearbox, and pushed on the clutch pedal till the reservoir was half empty.  Video: www.flickr.com/photos/43278150@N00/20649904200/in/dateposted-public/I then used my build buddy brick (not much of a talker, but very patient) to hold the clutch pedal depressed so I could check all the gears. I couldn't get them all, but that's another days' work.

|

|

|

|

Post by mawdo81 on Aug 24, 2015 10:47:10 GMT

Surely that's a gear linkage cable issue now though rather than a clutch issue? Congrats!

|

|

|

|

Post by Stewart on Aug 24, 2015 15:54:36 GMT

Liking the lime green! Let me know if you want to replace that banjo and bolt. I'm sure HEL can supply them.

|

|

|

|

Post by casesensitive on Aug 24, 2015 19:16:08 GMT

Surely that's a gear linkage cable issue now though rather than a clutch issue? Congrats! Yep, almost certainly. I'm calling the clutch line done (and there's no mistaking it in the tunnel for something else!), but I reckon the problem is the mech on the gearbox side, it's been incredibly stubborn, and the range of motion on the forward and backward direction of the gear lever (which is in and out on the g/b end) is tiny. I might bring the whole lot to an actual professional at some stage. |

|