|

|

Post by BobN on Aug 22, 2012 6:18:44 GMT

I really like the gear lever position. I think they have that position in some Honda cars and is more comfortable. Will you weld some steel somewhere to make it secure our are there alternative methods possible.

Bob

|

|

|

|

Post by Paul (madeye) on Aug 22, 2012 7:59:07 GMT

yes mate, ill use 1" CDS where the copper is and then triangulate it to brace it, then put 4 tabs on it like on the std. tunnel to mount the lever.

i just need to make sure the cables are not to too extreme an angle into the new minimal tunnel, and the handbrake i want is proving difficult to find.

|

|

|

|

Post by Paul (madeye) on Aug 22, 2012 12:10:31 GMT

we have new stuff.................... just arrived by courier. gone for a 0.75 front brake master due to caliper size. pedals are slightly different from the usual too. i was going to get tilton ones but couldnt justify the extra cash outlay      paul |

|

|

|

Post by Paul (madeye) on Aug 22, 2012 13:18:29 GMT

the doorbell has just gone..

more stuff.. its like xmas here today.

its bloody hard work to find a brand new, old mini radiator thats not either made in china or £350.

but i have one at last.

need to see how CBRocket has mounted his now

|

|

|

|

Post by Paul (madeye) on Aug 22, 2012 13:27:50 GMT

then all change, make it fixed and make the entire cavity an airbox,... talk about a job growing arms and legs. what about mounting an oil cooler in the reynard too? any thoughts? would be very effective from a cooling perspective. bloody awkward to mount i suppose. paul |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 22, 2012 16:08:18 GMT

This is a trend which RTR or MEV need to address, by the looks of it its due to the accute angle that its constantly sitting at, be it slightly emphasized y the suspension being at full travel while off the ground. i would refuse to accept that the company would sell a component that would fail without ever being used, and as there are multiple cases just on this site for one vehicle platform. somebody somewhere needs to look into which component it at fault. i am currently looking very closely at the suspension of my rocket, im quite unhappy with how it articulates and im looking to upgrade this before i go to get some colour applied. Hi Mark the same happened to mine like yours not even been on the ground. The ball joints are off a Austin maxi and i managed to get some new old stock QH QSJ602 off ebay , the rubber boots are 10x better. Cheers Tony. Regards to the above quote, RTR replaced mine for QH components, the batches that were failing prematurely were from RD. Mine failed after 2 months of sitting in the garage. They're apparently from a maxi  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 22, 2012 16:34:47 GMT

More food for thought, regarding your roll bar design, pay attention to your rear seatbelt upper mounting height. It's a sticky IVA point.  it won't affect the stock MeV builds, but it's vital on yours. Take pictures of the crush tubes etc for the test. |

|

|

|

Post by Paul (madeye) on Aug 22, 2012 17:28:48 GMT

More food for thought, regarding your roll bar design, pay attention to your rear seatbelt upper mounting height. It's a sticky IVA point.  it won't affect the stock MeV builds, but it's vital on yours. Take pictures of the crush tubes etc for the test. the cross member will be made exactly level with the holes in the seats, so there is no direction change at all mate. ;D cheers, for thinking about it though |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 22, 2012 18:10:53 GMT

More food for thought, regarding your roll bar design, pay attention to your rear seatbelt upper mounting height. It's a sticky IVA point.  it won't affect the stock MeV builds, but it's vital on yours. Take pictures of the crush tubes etc for the test. the cross member will be made exactly level with the holes in the seats, so there is no direction change at all mate. ;D cheers, for thinking about it though Should be ok, but it's worth the measure. Don't rely on the seat holes. The IVA contraption (tool) is a block with a plumb bob, and a 90 degree sliding measure. My robin hood failed, I changed the seats to a lower fitting sports fibreglass seat, and it passed. It was 1" or less, otherwise, full roll bar redesign.  |

|

|

|

Post by Paul (madeye) on Aug 25, 2012 7:30:22 GMT

|

|

|

|

Post by Paul (madeye) on Aug 26, 2012 11:07:01 GMT

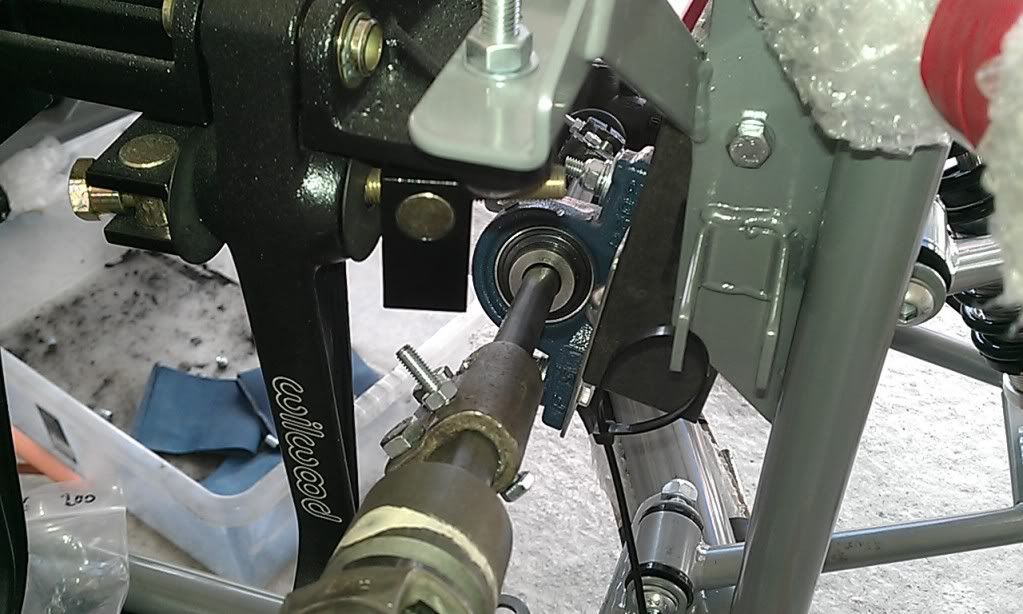

ok, i put a 12 hour stint in yesterday. i removed the seat mounts again. got the steering fully functional, just need a 17mm rose joint. With the discovery springs on the ends of the rack at feels really good at the end of the travel and helps self centre a lot. (i would advise anyone to do it even if your not putting in a QR) mocked up the firewall and finished the front bulkhead mockup mounted the rad (but forgot to take a pic of it)     |

|

|

|

Post by Paul (madeye) on Aug 26, 2012 11:09:15 GMT

does there have to be a defined angle in the steering so that in a crash it would sheer off in a given direction? i wanted as little movement in the CVs as poss??

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 26, 2012 18:01:04 GMT

Iva looks for a number of options regarding steering column, collapsible boss, extension rod angle etc. you have to fulfill a number of areas.

Personally, and I don't want to upset the AppleCart, but I don't understand why people use rose joints that are designed for axial movement, that are not the ideal solution? Plus they are about 20£+, versus a radial bearing, that I put on an alloy plate, that cost me £7.00 inc the mounting, and is correct for the job.

Pictures are on my build page, for me, it's the best and safest option.

|

|

|

|

Post by Paul (madeye) on Aug 26, 2012 18:16:15 GMT

basically its due to availability options, its easier to hang a rose joint from a small bracket than it is for me to fabricate your idea. my welding is limited and the end product will look crap and ill be unhappy about it. i have 17mm bar and will get an 18mm ID rose, there is no weight to it like in a car at sag. plus the QR will reduce the amount of rotation and ill keep it greased up. as for the angles, i best read the iva manual tonight   |

|

|

|

Post by airforceone on Aug 26, 2012 18:47:50 GMT

I was worried about the steering column moving as well at high speeds and under extreme wheel movement so I went a bit industrial on the bracket arrangement. No welding involved just good old angle iron and some high tensile bolts. So the end result was Nice and solid.  . Also gives a nice angle for the shaft for the IVA man. Cheap solution, think the bearing was £8, had the angle iron kicking around the garage. Doesn't look the nicest solution but I know it's very secure and safe, it's hidden by the radiator anyway. |

|