|

|

Post by fuoriserie on Nov 26, 2013 9:28:05 GMT

Another couple of days to completion then? Dark green does look good particularly in the sun, rain and sleet here in NW Derbyshire. Nice job and pictures. |

|

|

|

Post by snowbird1 on Nov 27, 2013 15:17:54 GMT

Another couple of days to completion then? Dark green does look good particularly in the sun, rain and sleet here in NW Derbyshire. Nice job and pictures. Thanks for the encouragement guys, now the car is home and indoors I can relax a bit but need to keep the pressure on for completion this winter  .  I made a crude 'H' frame so that I can pick up the body with the engine crane.  Two car garage is now a one car garage! The tin top will have to live outside for a while. |

|

|

|

Post by upstatecobraguy on Dec 3, 2013 16:31:13 GMT

|

|

|

|

Post by snowbird1 on Dec 4, 2013 14:32:22 GMT

Thanks Pat, I thought of using the rope and pulley system, my garage in Wales has nice big beams and I can lift a complete car on them, the AZ house is a modern stick built place - I wouldn't want to hang much more then a bicycle from the ceiling here!

The body can sit on the saw horses for now. BTW Lowes sells a folding steel saw horse the will support 1200lbs, I used them to support the car on my last build.

|

|

|

|

Post by snowbird1 on Dec 28, 2013 14:58:49 GMT

A bit of progress to report, it has been unusually cold and windy in the valley this month, I’ve been working with the garage door closed and not much light (I know – excuses excuses!). Working on the wiring; the car now has a RHD body and dash harness plus a NAS engine harness. A couple of kilos of stripped out wiring:

Still looking a positioning of components, fuse boxes, relays, solenoids etc. Trying body position – I want it to sit as low as possible but need room for the dash so may have to lower the steering column. That means I need to get the seat so I can check knee clearance, I’m looking at a pair of Kirkey vintage class bucket seats.

Also been checking the engine, not doing a full overhaul at the moment, the timing belt cover was missing some bolts, spacers and gaskets, parts of it had been rubbing on the timing belt and in other places it had rubbed through on the water pump belt.

I’m trying to decide if I should blank off the heater connections or fit a bypass hose. I think there should be enough coolant flow through the oil cooler/ISC circuit to operate the thermostat without the heater flow.

Has anyone seen a problem running with the heater circuit blanked off?

|

|

|

|

Post by gwnwar on Dec 28, 2013 18:38:29 GMT

John.. Was just about to start an email to you but stopped by here.. Good job on the wiring looks like 1/2 is removed..

Still some good items removed for resale.. cruise control unit, dash switch and wires, AC relays, Air bag unit and harness.

All removed the right way pulling the pins..

On the cooling system.. I would loop the 2 tubes together.. Were coolant comes out of the back of the head is the water that cools the cylinders and head you want to keep the flow moving back forward to be cooled..Don't need a hot spot there.. Cut and couple the 2 hoses together or if your auto store will let you look through there prebent heater hoses for one that fits point A to B.. Bend a piece of wire to shape needed.. With the cold weather it sounds like you need to go to Home Depot for some lights to mount on the wall for light..

FYI if you remove the head up/down ..hazard switch with out looping wires.. light won't work..

On the engine front cover parts you can put a Want To buy ad in the classifieds on Miata.net there are a couple of scrapers in CA. Keep the update coming..

|

|

|

|

Post by snowbird1 on Dec 30, 2013 15:34:16 GMT

I’ve been trying to figure out the coolant flow on the MX5 engine, in most engines the coolant is pumped through the cylinder block then up to the cylinder head through large ports in the rear and forward to the thermostat housing.

Without taking the head off I’m not sure of the flow path on the MX5, apparently it is similar the transverse Protege engine that has the thermostat at the rear of the cylinder head.

It appears the Miata has continuous coolant flow from the rear of the head, bypassing the radiator and then the thermostat controlled flow through the radiator. On many engines the bypass flow is closed off when the thermostat opens.

|

|

|

|

Post by gwnwar on Dec 30, 2013 23:34:44 GMT

John just email a flow chart for a miata engine hope it helps. click on pic or use keys Ctrl + to make large..

|

|

|

|

Post by R2S on Jan 5, 2014 22:08:01 GMT

Have you done away with ABS?

|

|

|

|

Post by snowbird1 on Jan 8, 2014 3:24:01 GMT

Have you done away with ABS? Yes, I had already plumbed it for the UK - non ABS donor. Not sure how well it would work, the manufacturer calibrates the system for vehicle weight and tyre size so the operation would be compromised on the Replicar. Having said that it looks like a fairly basic system, 3 channel operation even though it has 4 sensors so it may not be that sensitive. |

|

|

|

Post by snowbird1 on Jan 8, 2014 3:41:32 GMT

John just email a flow chart for a miata engine hope it helps. click on pic or use keys Ctrl + to make large.. Looks like the BP engine relies on the coolant flow through the heater circuit for cooling to the rear cylinders. I considered fitting an auxiliary radiator but then it would need it's own thermostat to achieve even warm up, so we will keep it simple with a bypass hose. |

|

|

|

Post by snowbird1 on Jan 8, 2014 3:59:22 GMT

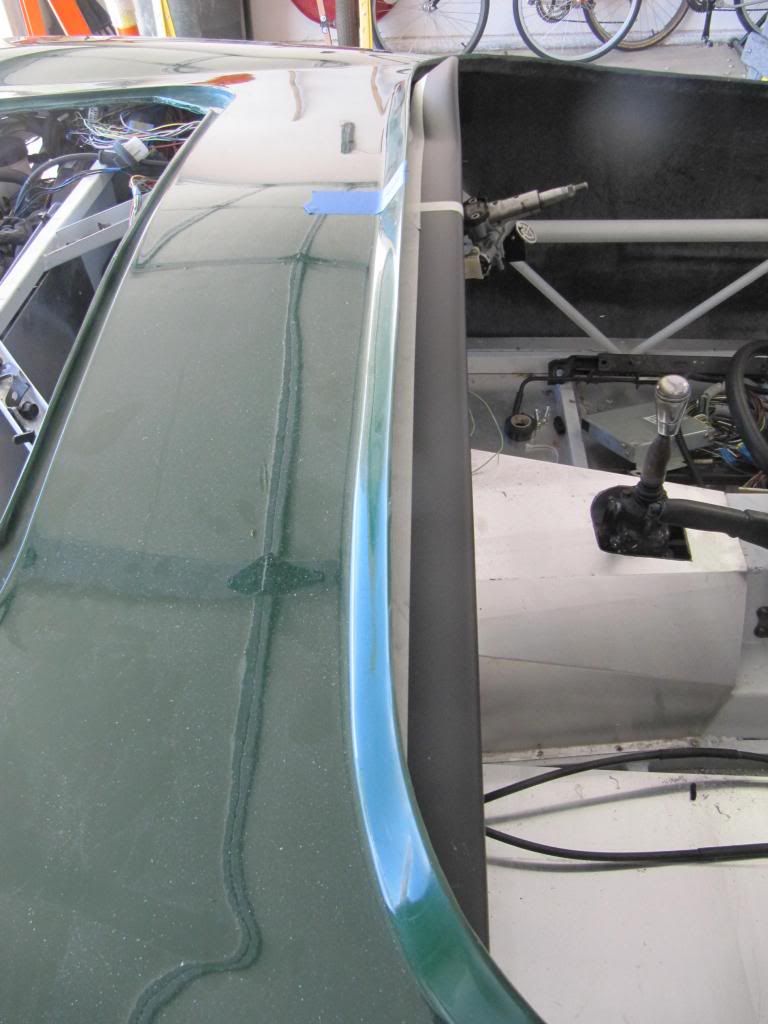

I wanted to try out the 160mm hole saw for the headlamps, worked great;  Now I need to find a use for a couple of very large 1/4" GRP washers! Trial fit of the body and dash, looks like I need to lower the steering column a bit, need to get the seat fitted to check knee room.  Starting to get the knack of body R & R;  |

|

|

|

Post by R2S on Jan 8, 2014 13:33:06 GMT

Haven't decided what to do with ABS yet, back when i used to work on my cars none had ABS, and i never managed to crash one (hope i am not tempting fate) so not sure i see the need to keep.

Have you worked out yet how to cut down the perspex headlamp bubbles to the right sized/shape for both sides in order that the profile is the same/match?

|

|

|

|

Post by snowbird1 on Jan 8, 2014 13:37:29 GMT

Have you worked out yet how to cut down the perspex headlamp bubbles to the right sized/shape for both sides in order that the profile is the same/match? No - that's the next challenge! |

|

|

|

Post by R2S on Jan 8, 2014 13:51:22 GMT

Good luck. I was wondering whether you could fill bubble with expanding foam (assume your perspex is lined like mine) and then sand down from rear a small piece at a time once foam has set removing foam on completion?

Stu if you read this do you have any thoughts?

|

|