|

|

Post by mr9802 on Apr 22, 2015 23:48:03 GMT

Looking good!

|

|

|

|

Post by carlyd on Apr 24, 2015 11:24:04 GMT

Well after almost 3 weeks I finally have my 4th wheel which was damaged by the muppets at Parcel Farce and had to be shipped from Momo in Italy to me.

I'll be fitting that this weekend and dropping it to the floor. Exciting times

|

|

|

|

Post by carlyd on Apr 29, 2015 14:37:54 GMT

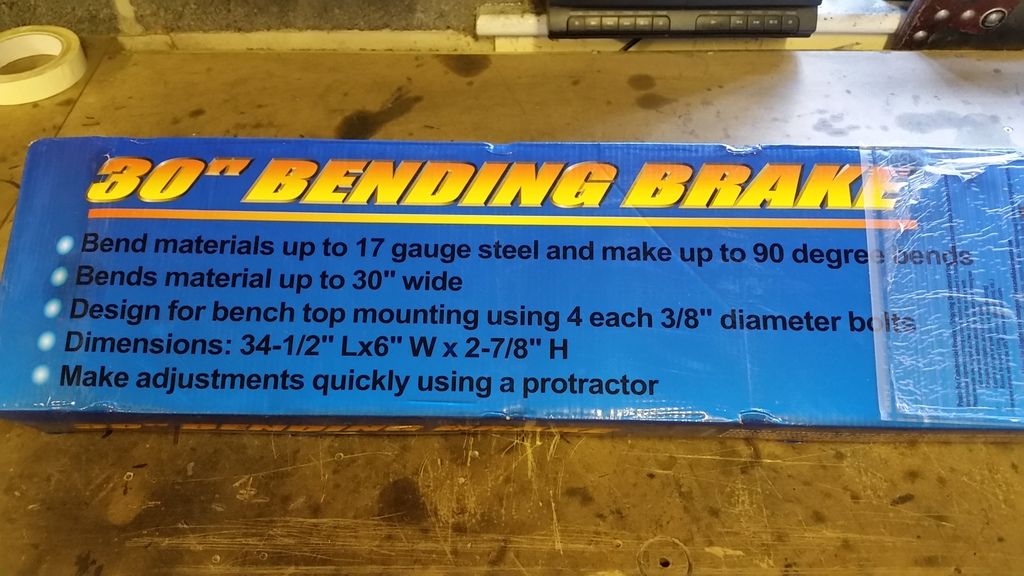

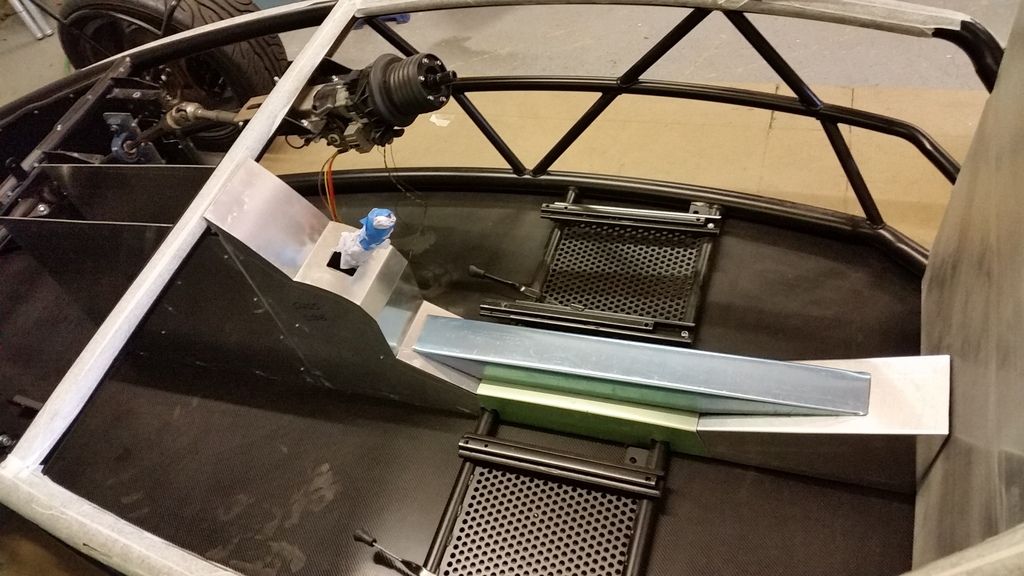

I wanted to fabricate my center tunnel so I bought a bender to give a neat and tidy bend  It's really easy to use so I just need to cut the handbrake hole and get it welded up now.  I also made a mock up of the battery and ECU box which will sit in the center console behind and above the gear selector. It's the best place I could think of putting it to keep it safe and dry.  ![]() |

|

|

|

Post by carlyd on May 11, 2015 9:20:13 GMT

As I decided to go for the side pods to house my radiators I attempted to fit them. As usual with my build nothing is standard so the side pods wouldn't fit.. as I have the race spec chassis with the extra brace bar down each side of the chassis and extra support bars. I decided it was time to butcher the pods to make them fit.    I also decided to cut the radiator fuller caps off and have them welded up.  Now I need to reinforce the pods on the inside, I'm going to do this will ally and fibreglass. I'll post more pics when they are done. |

|

|

|

Post by carlyd on May 11, 2015 9:26:30 GMT

I then decided to tackle lengthening the Honda wiring loom (oh joy) I cut the wires one by one and lengthened them by 2.2 metres, this will allow me to place the ecu under the bonnet next to my battery, as that's the driest place I could think of, it also means I can place all my wiring, fuse boxes and relays under the bonnet. It's a bit of a mess.  and I still have the main engine relay, immobiliser, 3rd ECU plug and data plug to wire in yet, this is just the engine electrics as I'm keeping engine and lighting separate. I've soldered all joints and shrink wrapped them as I didn't want to use those electrical connectors due to them being unreliable. I still have lot's to do on the wiring so I'll add progress as I do it. |

|

|

|

Post by kiwicanfly on May 11, 2015 10:15:20 GMT

I tried some telephone connectors to extend my push button start wiring. Totally crap, gave all sorts of poor connections, took up loads of room and looked awful.

Went back to solder and heat shrink.

Found one of those "third hand" thingies worked a treat for holding wires whilst soldering.

|

|

|

|

Post by carlyd on May 11, 2015 10:55:25 GMT

Found one of those "third hand" thingies worked a treat for holding wires whilst soldering. I used a vice to hold one wire and twisted the other to it before soldering. I may look into a 3rd hand, that's gotta come in useful  |

|

|

|

Post by kiwicanfly on May 11, 2015 19:24:53 GMT

Third hand was most useful when making joint where wiring was in place but needed modifying.

|

|

|

|

Post by carlyd on May 12, 2015 8:21:32 GMT

Third hand was most useful when making joint where wiring was in place but needed modifying. I've just purchased a 3rd hand. |

|

|

|

Post by casesensitive on May 12, 2015 11:38:52 GMT

Don't mean to hijack, but aren't soldered connections meant to be brittle? I was under the impression auto wiring should be crimped connectors only where possible?

|

|

|

|

Post by carlyd on May 12, 2015 13:18:58 GMT

Don't mean to hijack, but aren't soldered connections meant to be brittle? I was under the impression auto wiring should be crimped connectors only where possible? hmmm I've not heard of that before, there are already some soldered connections in my loom from the factory. Also where my joins are there are no bends in the wiring so should be ok. |

|

|

|

Post by kiwicanfly on May 12, 2015 19:41:32 GMT

I have heard that but thought it was at the connectors as the wire often bends at, or close to, them.

If the wire was running in a straight line I would have thought it ok.

On the subject of wire joints treat yourself to a proper set of wire crimping pliers and use unsheathed connectors ( cover with heat shrink after crimping). These connectors fold onto the wire rather than simply deforming a tube and are so much better.

|

|

|

|

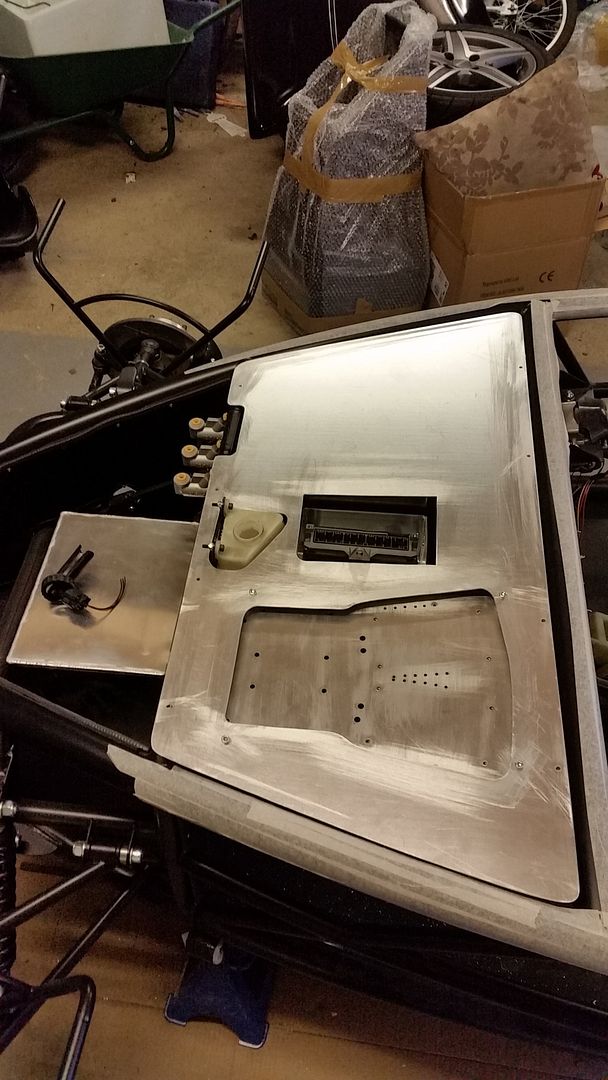

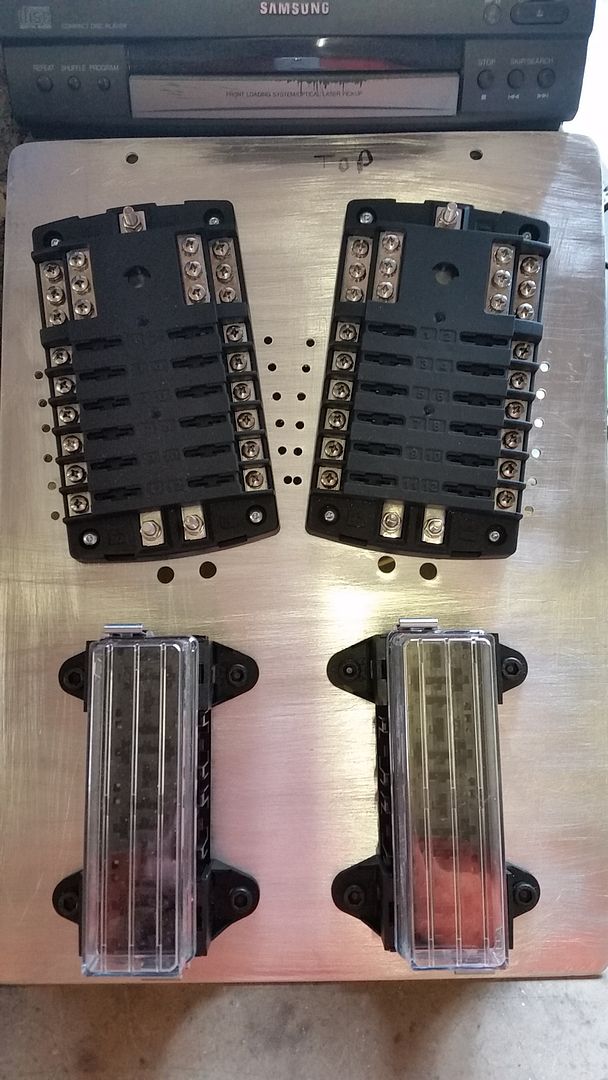

Post by carlyd on May 18, 2015 11:56:10 GMT

I started making the mountings for the fuse and relay box's. I am putting them under the bonnet (close to the battery and ECU) but realised after making a mounting sheet that the bonnet would not close with the fuse and relay boxes mounted. This is my solution.    |

|

|

|

Post by carlyd on May 18, 2015 11:59:14 GMT

|

|

|

|

Post by mawdo81 on May 18, 2015 12:36:47 GMT

I think that may be classed as in the passenger compartment. If I was you I'd Box it in, sealed to the passenger foot well with drain holes through to the tank.

That said, its just my reading of the manual, I haven't tried to take anything through an IVA.

|

|